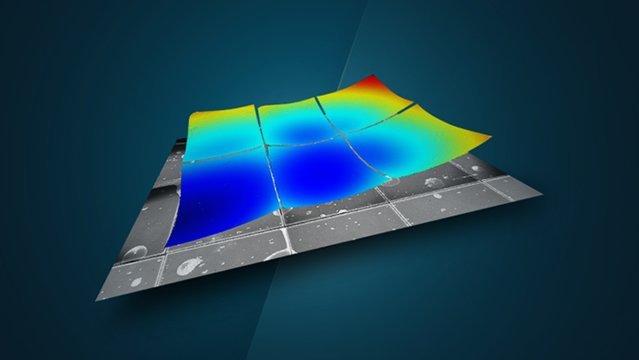

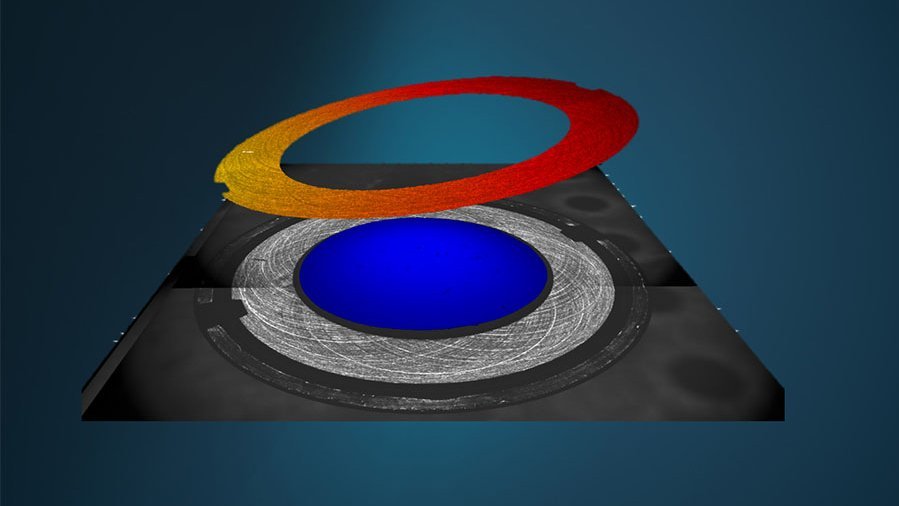

Combined measurement of form +roughness

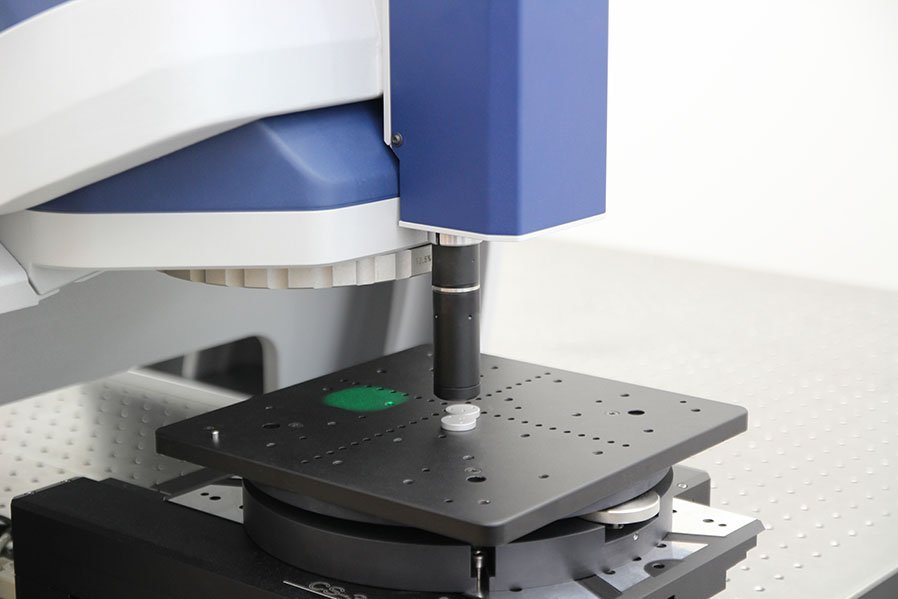

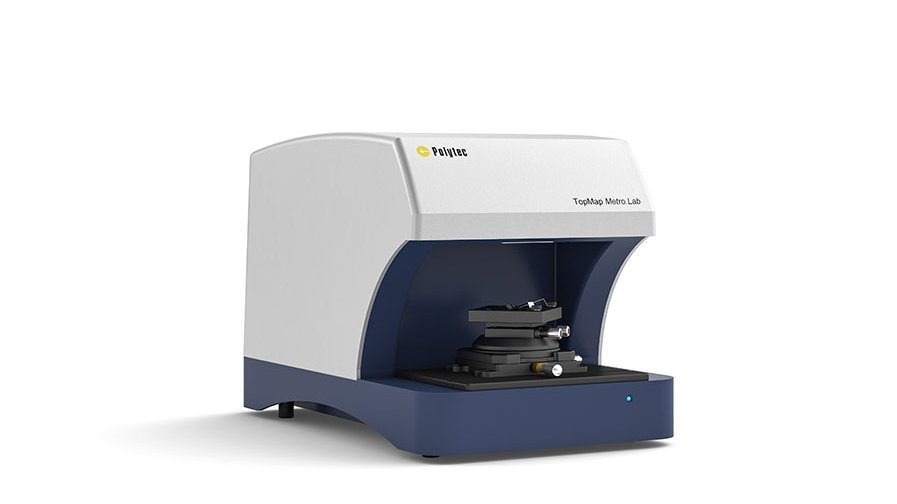

The TopMap Pro.Surf+ conveniently determines surface roughness and form deviation in a single measurement system – precise, reliable and cost-efficient. The additional roughness sensor and smart data acquisition take the high-end profilometer TopMap Pro.Surf to the next level forming an all-in-one instrument. The resulting Pro.Surf+ is ideal for measuring precision surfaces – in the metrology laboratory, close to production and even right in the production line thanks to a high level of repeatability.

outstanding single FoV

(extended 230 x 220 mm)

flexible, large Z range

high vertical resolution

warranty + lifetime software updates

Highlights

- Quick and precise 3D surface + roughness characterization

- Multi-sensor system to capture all surface and structural details

- Non-contact measurement and traceable results

- SST Smart Scanning Technology + filter wheel master any surfaces, materials and reflectivities

- Capture large or multiple samples in one shot with exceptionally large workspace XYZ 230 x 220 x 70 mm

- Telecentric lens measures even deep and recessed areas

- Automatic sample recognition avoid mechanical fixture

- Free 4 year warranty and lifetime Software updates