Highly sensitive to implants

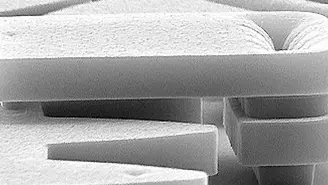

Historically, strictly complying with a defined level of surface roughness has been the only way of inserting implants without any complications. That is why, to achieve this level of quality, it is immensely important to check the results using precise surface measurement systems after what can sometimes be a time-consuming surface treatment process.

Form deviations or roughness outside of defined tolerances can be extremely unpleasant in the sensitive inner mouth area, where dental implants come into contact with both the gums and microorganisms. In certain cases, some surfaces need to be given special treatment if the desired properties are to be achieved. “Organic coatings” increase the implants’ durability. Polytec’s range of precise surface metrology products helps you to detect deviations and thereby achieve the desired surface condition.

Surface characterization on implants

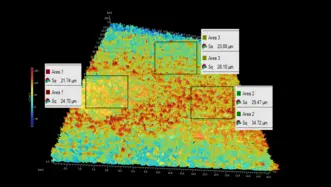

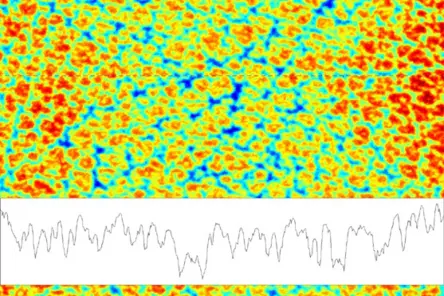

Joint implants indeed are sensitive measuring examples. The only way that the body can accept the implants and not simply reject them is if they have perfect surface properties. If artificial joints have too rough a surface, the probability of undesirable microorganisms forming increases. In contrast, shortcomings in the polishing process can have a negative impact on the implants’ service life. Using TopMap surface measurement systems from Polytec is the ideal way of ensuring that you find that perfect “middle ground” every time

Fitting surface profiler

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

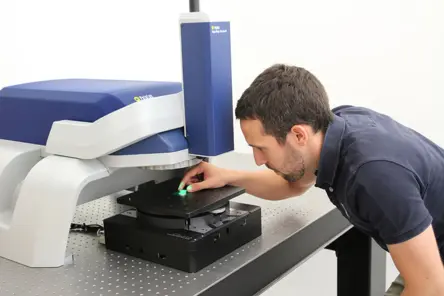

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related measurement tasks

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.