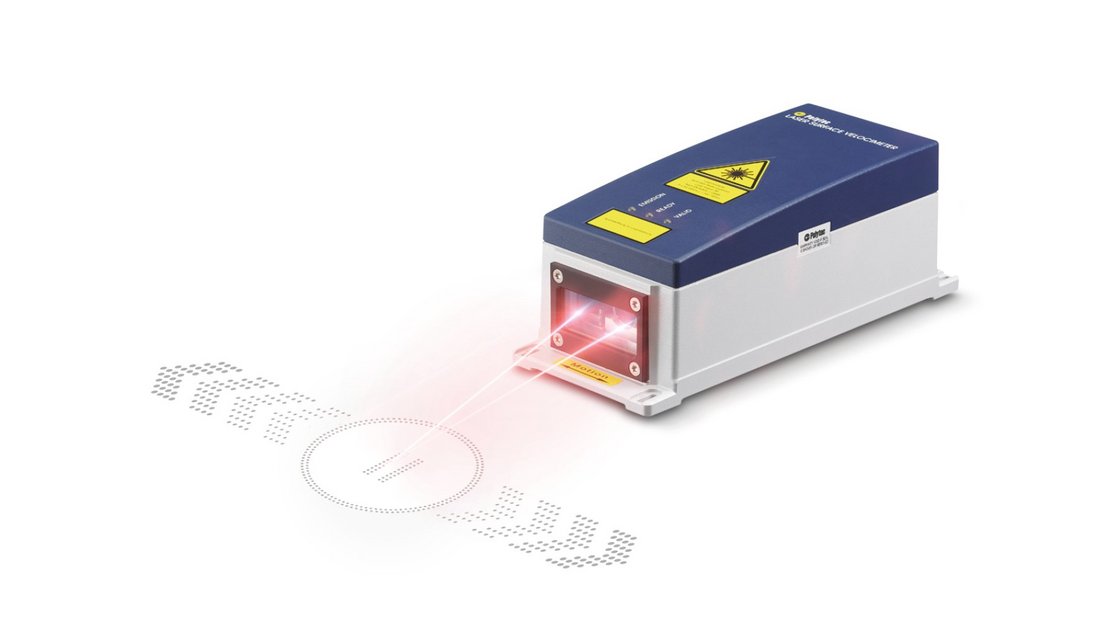

ProSpeed® optical length & speed gauges

Speed gauges are essential for process control when producing strip material, e.g. in steel mills or paper manufacturing. Knowing the exact process speed and the derived strip length allows for optimizing any manufacturing process of sheet and endless material, for casting, rolling and more. Polytec provides a non-contact measurement alternative of laser-based speed gauges for reliable process control. Learn more about how ProSpeed® optical sensors will take your production process control to the next level and test us!

warrabty on new sensors incl. laser diode

sensor exchange program (excl. shipping)

building laser sensors

customers being long-time partners

Typical industrial processes of ProSpeed speed gauges

Speed measurement

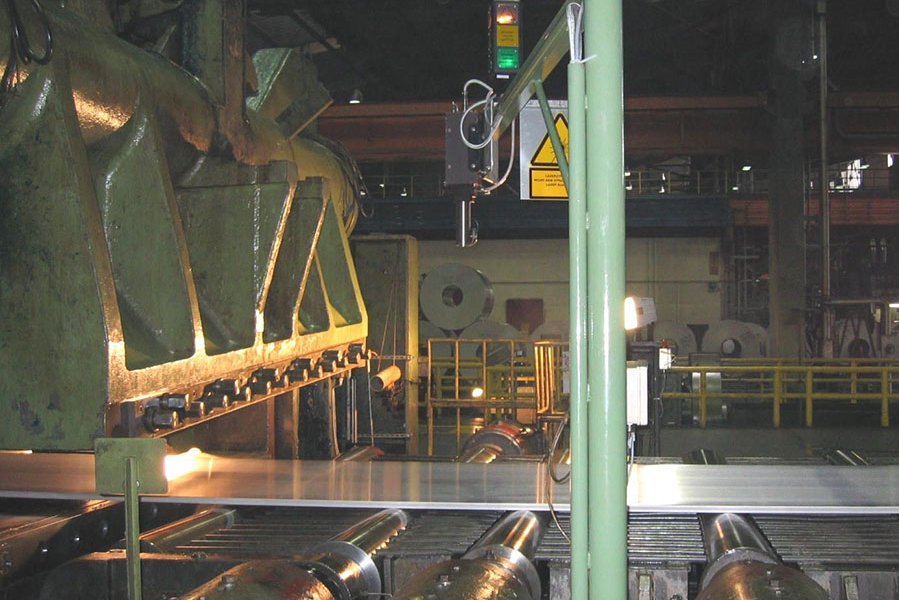

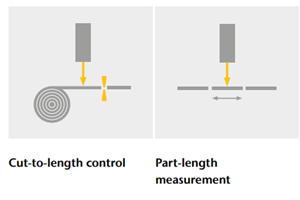

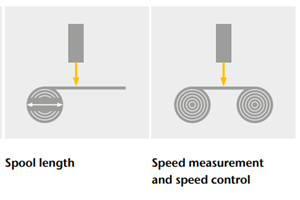

Process speed or velocity measurement is the basis for many steps in production processes such as cut-to-length control, depending on the manufacturing process sometimes speed synchronization, or differential speed measurement and more. In these processes, the ProSpeed® gauges use the laser Doppler effect for precise speed measurement, avoiding contact of the encoder with the good's surface and preventing slippage and wear, resulting in utmost precision and reliability in process control.

Length measurement

Whether in casting processes, rolling mills or any cut-to-length control, length verification of cut products such as rods, tubes, coils, panels and sheets, plate positioning in U- and O-presses for tubes, material tracking for sheet materials, winding sheet material up to position sensing and elongation... The number of speed and the respective distance traveled, are crucial for process control. ProSpeed® laser-optical gauges have become established devices in controlling production lines all over the world.

Gauges for cut-to-length, casting & rolling

Providing electrical signals just like any classic encoders, Polytec speed gauges provide a seemless integration into any manufacturing line. Laser-based gauges show exceptional measurement performance in challenging conditions, for example when it comes to producing red-hot metals, handling material in humid, hot or dustry manufacturing environments. ProSpeed® gauges provide stable and all-time reliable measurement signal for continuous production, reducing measurement uncertainty caused by slippage or wear.

3yrs warranty incl. laser diode, gauge exchange - our PolyXpert services!

Advantages of optical speed gauges

- Speed gauge measures reliably inline, forward & backward motion plus standstill

- Optical speed gauges avoid contact, slippage and wear

- High flexibility with 3 m stand-off distance

- Outstanding depth-of-field up to 200 mm compensating varying distances

- Enhanced connectivity featuring web interface, Ethernet and fieldbus protocols

- Multi-user access: 3 via Ethernet + 1 serial

- Laser technology for harsh & hot environments: IP66 and IP67; certified mechanical shock & vibration resistance

- 3 years warranty, gauge exchange pool, fast & onsite support

Describe your case, request an onsite proof-of-concept!

Why optical speed gauges promise more reliable process data

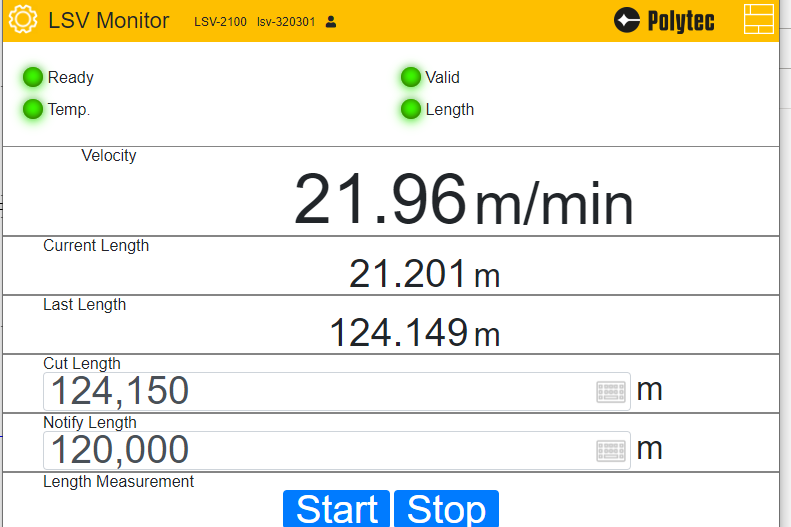

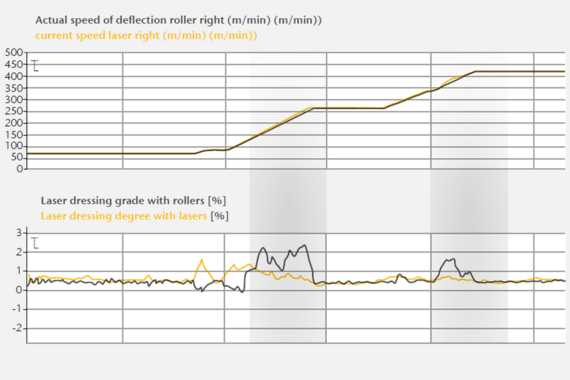

The image depicts a visualization of measurement data captured by a laser speed gauge system in the industrial process of cold rolling. The described changes in velocity or position of the sheet material allow patterns, indicating regular or periodic motions, fluctuations, or irregularities in the measured parameter. Based on this data input, the PLC can synchronize and harmonize all related process steps and regulate the mass flow process.

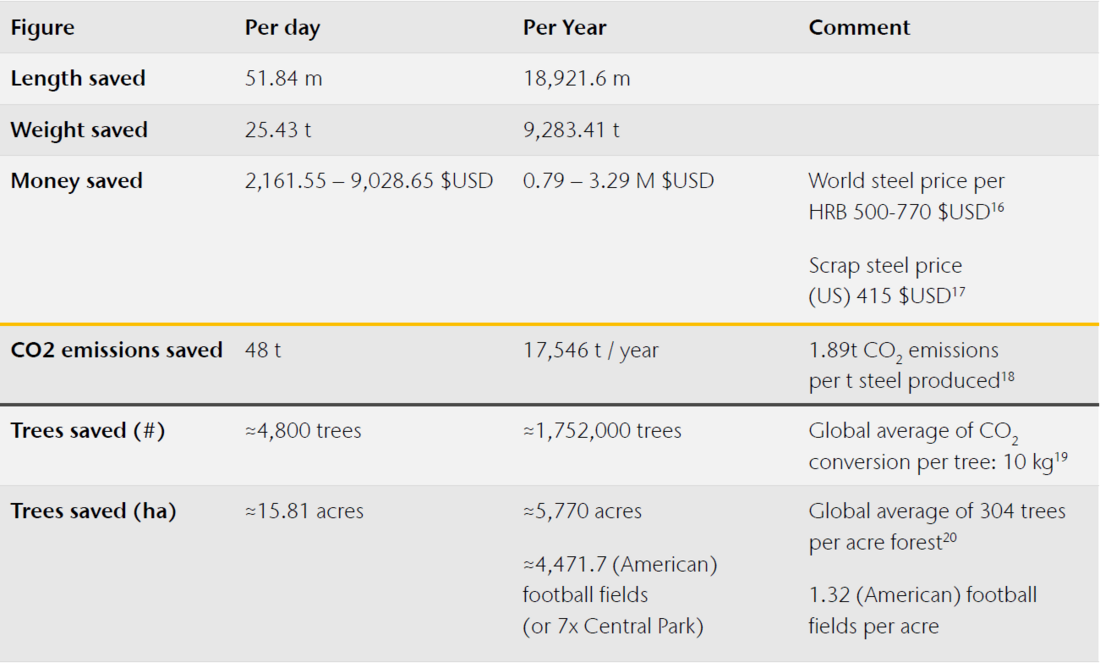

Speed gauge cost & ROI calculation example on a 5-strand billet caster

Contact us for cost, configuration and speed gauge integration

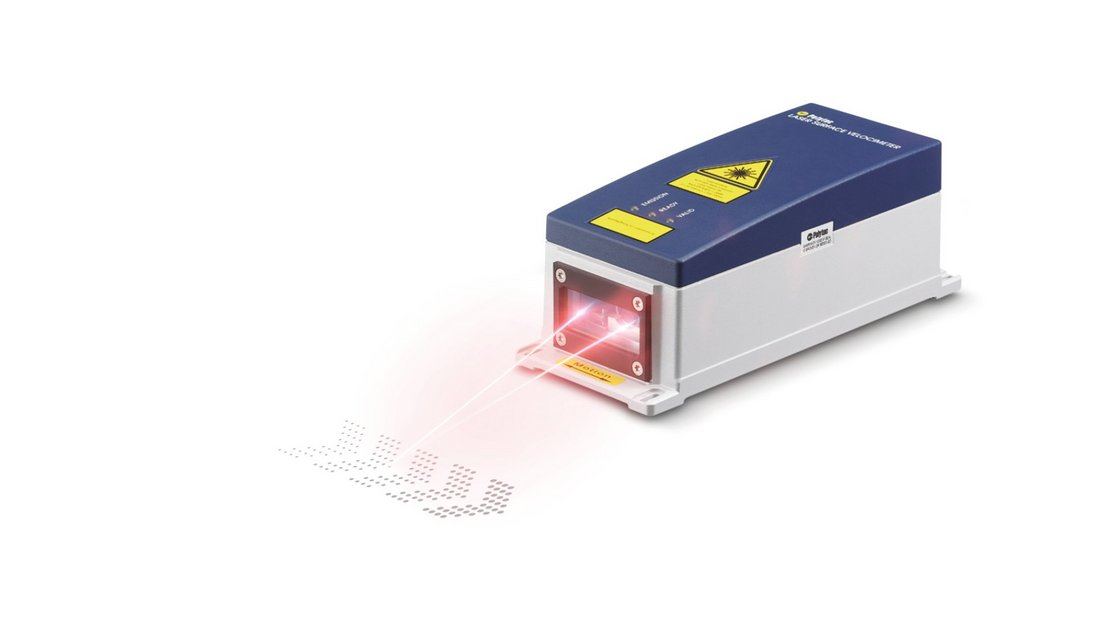

Basic principle of laser-Doppler speed gauges

ProSpeed® optical speed gauges use the laser Doppler effect for evaluating the backscattered laser light from a moving object. Two super-imposed laser beams generate an interference pattern of bright and dark fringes on a monitored surface. As this surface of a sheet material in a manufacuring line moves through the fringe pattern, the intensity of the light scattered back results in a modulated frequency. This frequency modulation is measured by the photo receiver of the speed gauge, being directly proportional to the process speed or object velocity.

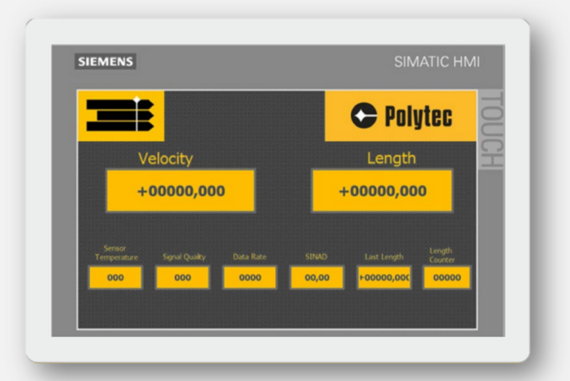

Speed gauge for process automation using Profinet (Siemens PLC S7-300)

The latest generation of ProSpeed® gauges come in a rugged design with an all-in-one integrated optics and electronics. The enhanced connectivity concept allows for a seemless integration into any production line. This application note describes the integration of the ProSpeed® LSV PROFINET interface for example into a Siemens PLC S7-300 using the project engineering software TIA-Portal.