Length measurement on roll-fed material and piece goods

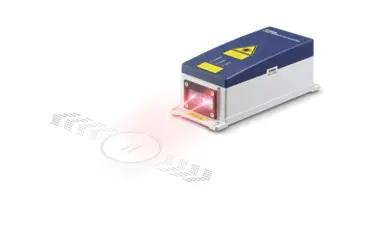

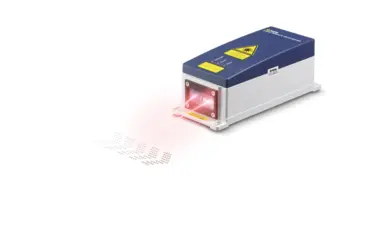

Determining the velocity provides the basis for measuring the length. The length is calculated based on the velocity profile while the measured object passes through the measuring location. LSV Laser Surface Velocimeter are laser-based length and speed sensors, that automatically recognize whether material is in the measuring location and can start/stop the length measurement accordingly. To achieve maximum measurement accuracy the LSV offers you the option of connecting light barriers as a means of starting or stopping the length measurement. This means you can link up several light barriers with one another to obtain a variety of application options. This may include, for example, controlling the length measurement using both trigger inputs, thereby increasing accuracy.

LSV Laser Surface Velocimeters are the ideal metrology in manufacturing because they measure on almost any surface and still work with contaminated surfaces in production lines. The non-contact measuring principle avoids inaccurate measurements caused by slippage and wear. The produced good remains intact thanks to the non-invasive method. Another benefit of Polytec systems is the flexible interface concept – it enables length readings via encoder output, serial interfaces, LAN, Profibus and Profinet.

Length measurement and control

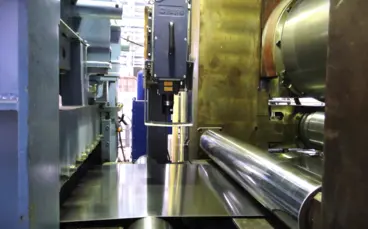

Polytec LSVs are used for a variety of length measurement processes in the metal industry:

- length verification of cut products such as rods, tubes, coils, panels and sheets

- plate positioning in U- and O-presses for longitudinally-welded large-diameter tubes

- cut length control of flying or vertical saws and shears

- material tracking for sheet materials

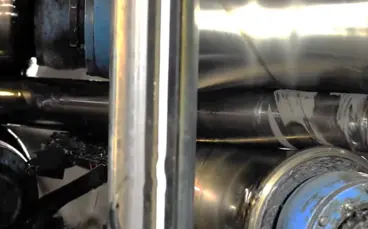

Rotary tube saw control

These are increasingly being used in tube rolling mills. The saw blade is moved around a circular course at the speed of the tube. The movements must be exactly synchronized and that with speeds of up to 10 m/s. The Polytec LSV measures tube speed without slippage or wear to control the rotary tube saw. Using the LSV allows for an exactly vertical cut and reduces the length tolerances to a minimum.

Optical length and speed measurement in steel, aluminum and metals production

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.