Elongation process control with laser precision

For processing steps which involve elongating (extending) products, it is important to measure and monitor the degree of elongation – since this has a substantial influence on product quality and further processing. If the degree of elongation is too low, requirements for subsequent processing steps may not be met. If, on the other hand, the degree of elongationis too high, this can have a negative impact on product characteristics or, in the worst case, the product may be damaged. In order to determine the elongation, the velocity is measured both before and after the processing step and the degree of elongation is calculated based on the results of the velocity measurements.

Polytec laser sensors allow non-contact elongation process control, leading to improved yield and reduced scrap!

Non-contact measurement & elongation monitoring

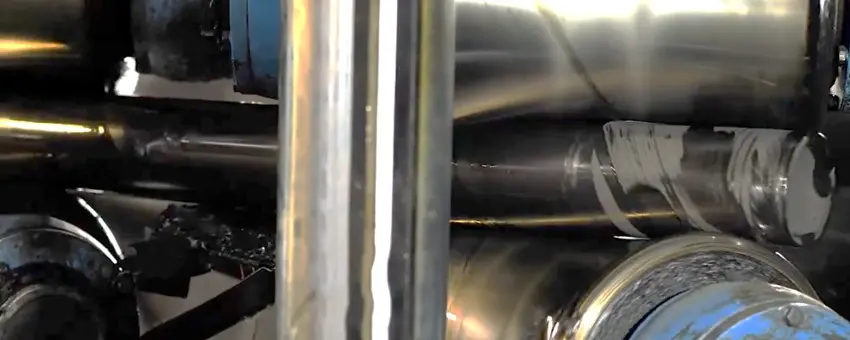

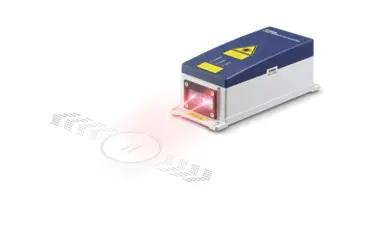

Laser Surface Velocimeters (LSVs) from Polytec are ideally suited for elongation processes, reliably measuring on any product surface - even contaminated ones in dusty, oily and rough production environment. The non-contact measuring technique eliminates negative influences on accuracy, such as slippage or wear, immediately and leave the monitored product intact, too. The increased accuracy of the velocity measurement allows a better monitoring of the velocity difference, providing better insights into the elongation process, increasing product quality while at the same time reducing waste.

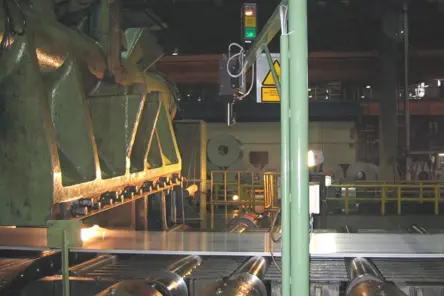

Skin-pass & stretch degree measurement in elongation

Polytec LSVs are established sensors for elongation processes in the metal industry, especially for measuring the skin-pass degree in skin-pass or stretching mills. The skin-pass degree in cold strip skin-pass rolling is determined by the difference in strip velocity at the input and output of the roll stand, which in the past has been measured mechanically using tachometers for elongation control. Using two Polytec LSVs prevents the occurrence of measuring errors owing to slippage and wear and the skin-pass degree measured may be used as a control parameter for adjusting the rolls. Using Polyec optical elongation sensors, major German stainless steel manufacturers confirmed the uncertainty going down to just ± 0.02% of the skin-pass degree measurement.

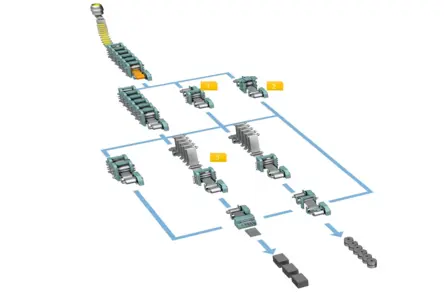

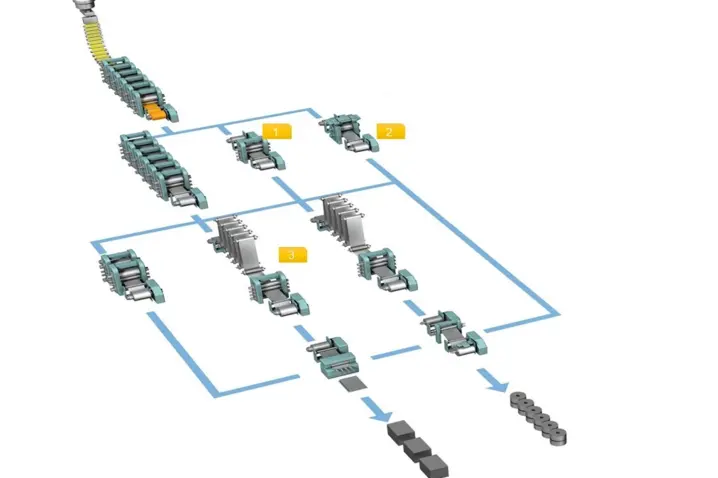

Speed synchronization in aluminum production

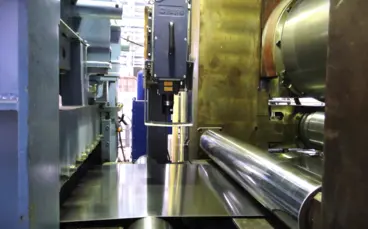

In the largest aluminum smelting and rolling plant in the world, the length and velocity of aluminum sheets in the manufacturing process are measured simultaneously using non-contact laser Doppler measurement technology from Polytec. Several Polytec LSVs are integrated in the manufacturing process and provide readings for plant control.

Typical applications for LSV Laser Surface Velocimeters in elongation processes:

- Entry and exit speed measurement for mass flow and elongation control in a reversing cold rolling mill

- Entry and exit speed measurement for mass flow and elongation control in 20 high roll mill stand

- Entry and exit speed measurement for elongation control in a temper / skin pass mill

Optical length and speed measurement in steel, aluminum & metals production

How to: Sensor integration & automation with PROFINET

Polytec has offered gateways for PROFIBUS, PROFINET and EtherNet/IP for many years. With PROFINET and EtherNet/IP integrated into the LSV sensor head, the interface allows not only the cyclic measurement data acquisition in real time, but also the acyclic writing of parameters and control of the laser. This application note describes the integration of the ProSpeed® LSV PROFINET interface into a Siemens PLC S7-300 using the project engineering software TIA-Portal, describing a step-by-step cyclic and acyclic data exchange.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.