Dear visitor, in order to be able to watch our videos please accept the cookies. All information about the usage of cookies can be found in our privacy policy

Optical 3D surface profilers

Optical 3D surface profilers from Polytec are innovative, high-precision and non-contact tools for characterizing the surface topography in 3D. They are based on the principle of white-light interferometry, which is also known as coherent or vertical scanning interferometry or coherence radar. Thanks to their large vertical range, nanometer resolution and areal measurement, they are perfect for contactlessly measuring the flatness, step height and parallelism of large sample structures – on almost every material.

3D surface profilers

White-light interferometers are optical 3D surface profilers and the ideal solution for inspecting functional surfaces with utmost precision and reliability. TopMap surface metrology systems measure form parameters like step-height, waviness, flatness and parallelism, as well as roughness and microstructures in all environments from research laboratories, close to and in production lines.

Software & accessories

Learn more about our software. Our mission is to provide intuitive and efficient measurement systems. Based on this promise, we provide comprehensive measurement and analysis software for easy filtering and analysis of measured data. Use automated analysis features for routine inspections and benefit from the open software architecture for application-specific and user-configurable interfaces. Any more questions? Contact us!

Service & support

Free 3-year warranty on new gauges, outstanding service and reliable support: Our PolyXpert services comprise various packages: from on-site support to sensor integration and installation, we help find custom solutions, dedicated training, calibration or repair, plus our fast and uncompromising sensor exchange program. Our ProSpeed® optical length and speed sensors come along with a reliable partnership, know-how and trust! Proof us!

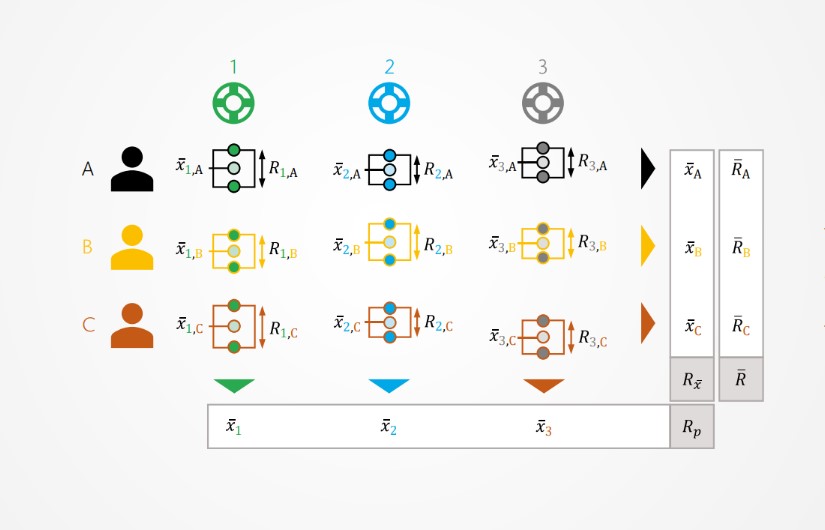

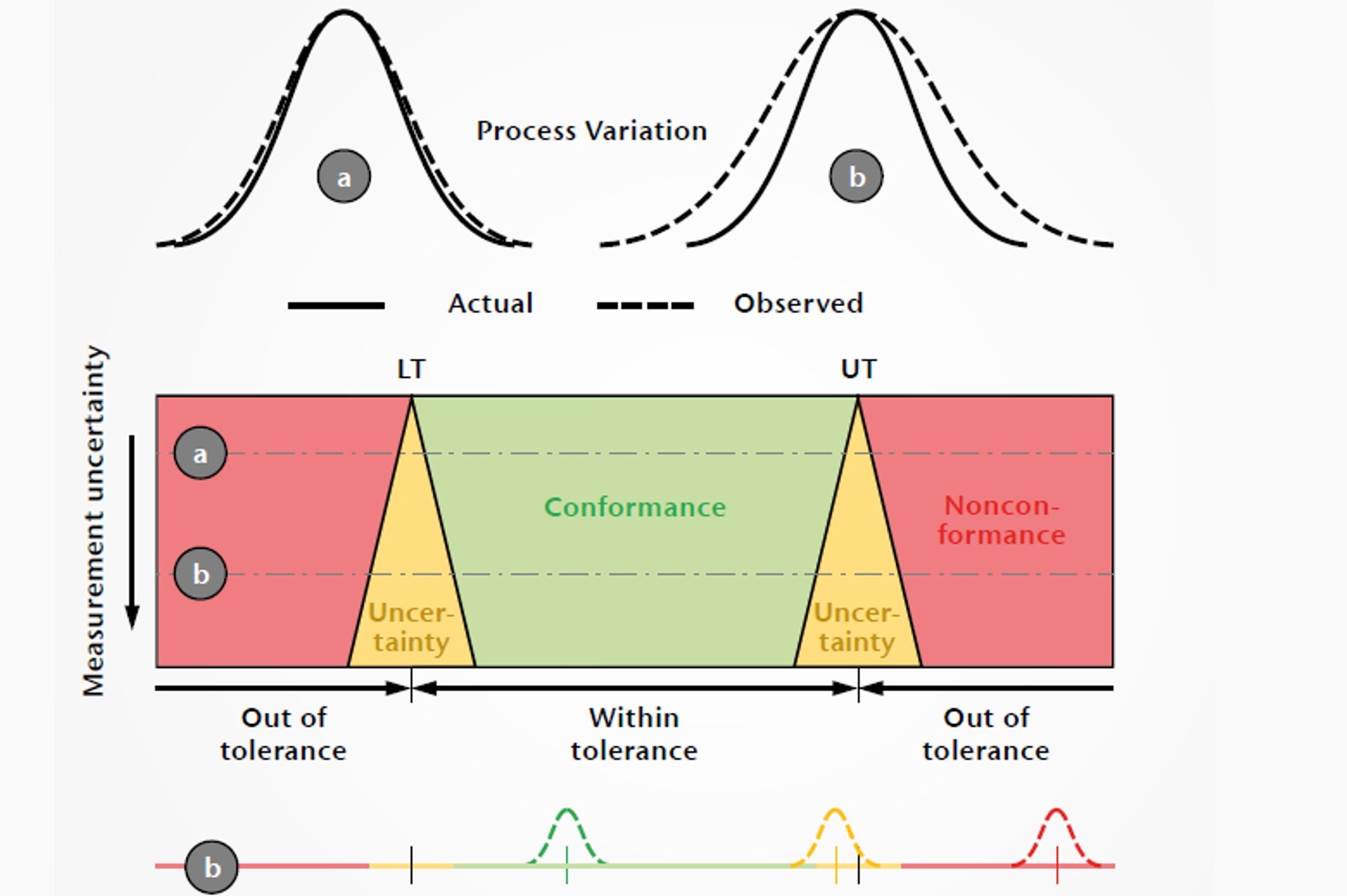

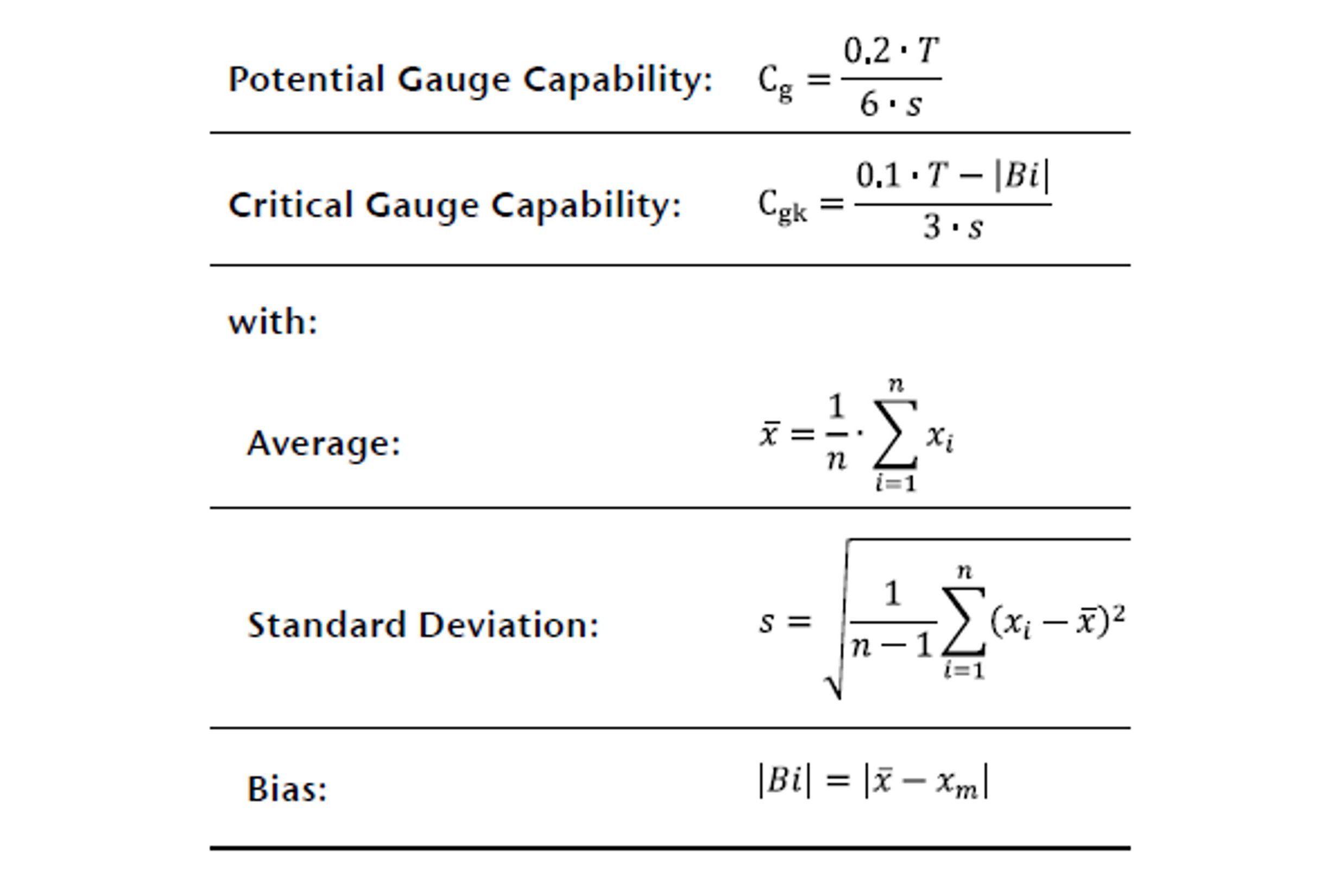

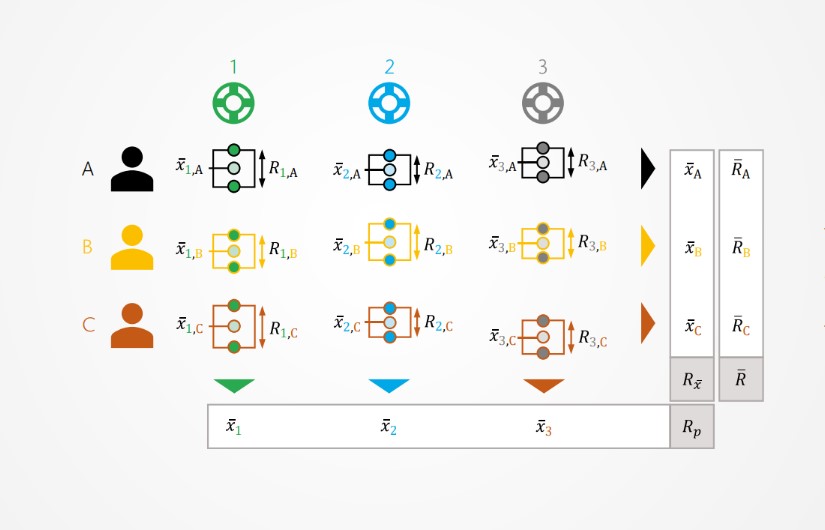

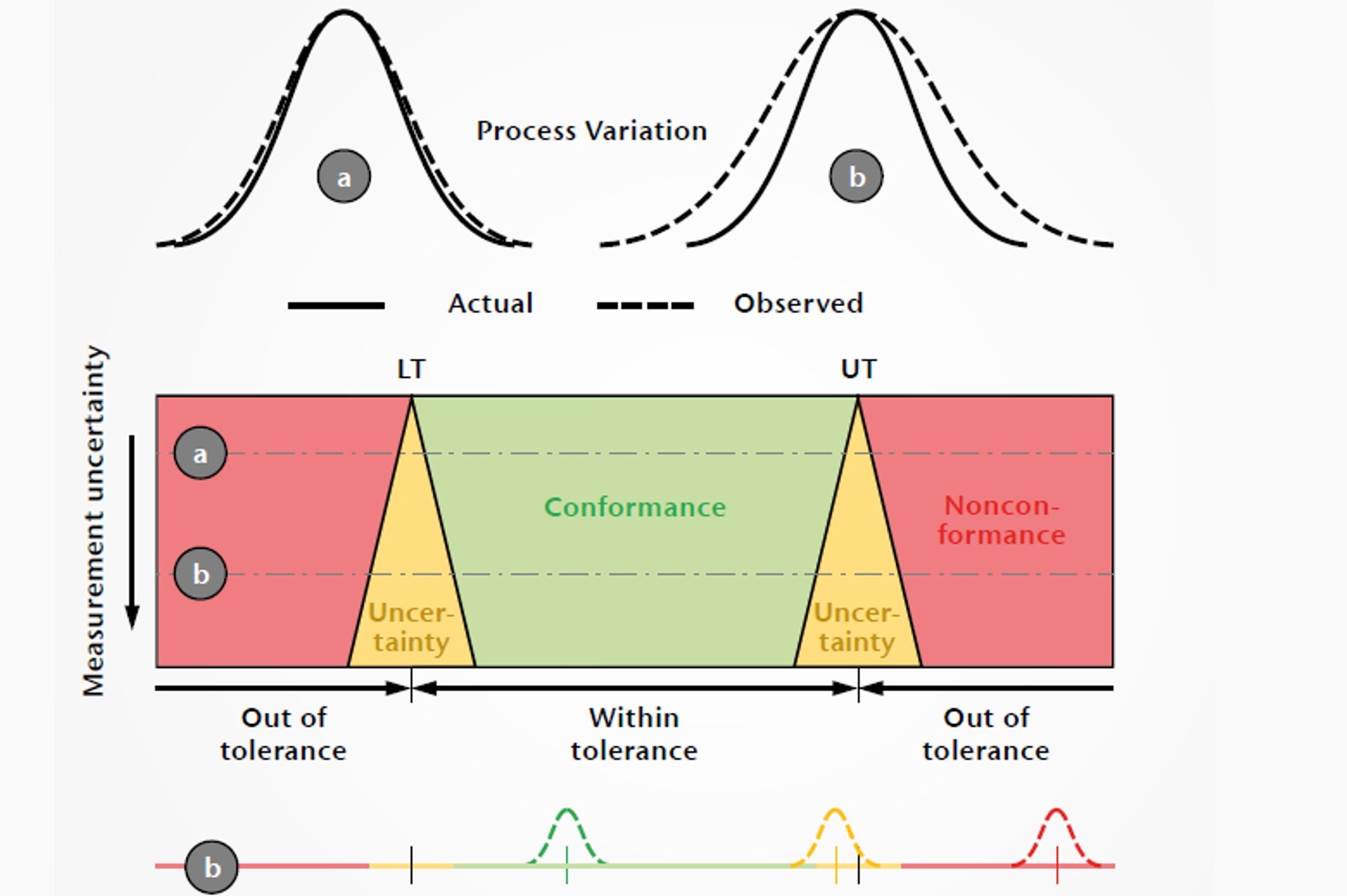

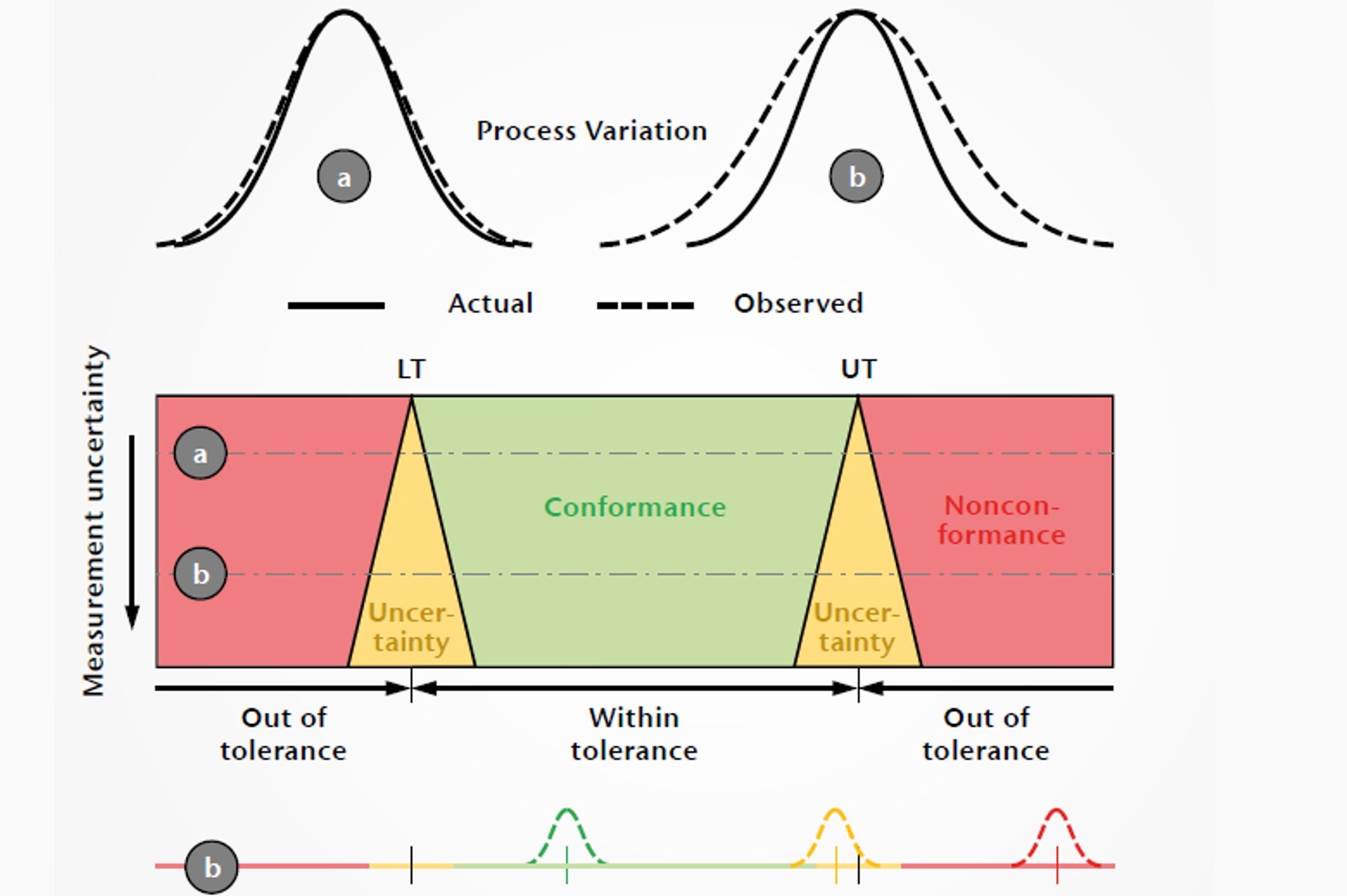

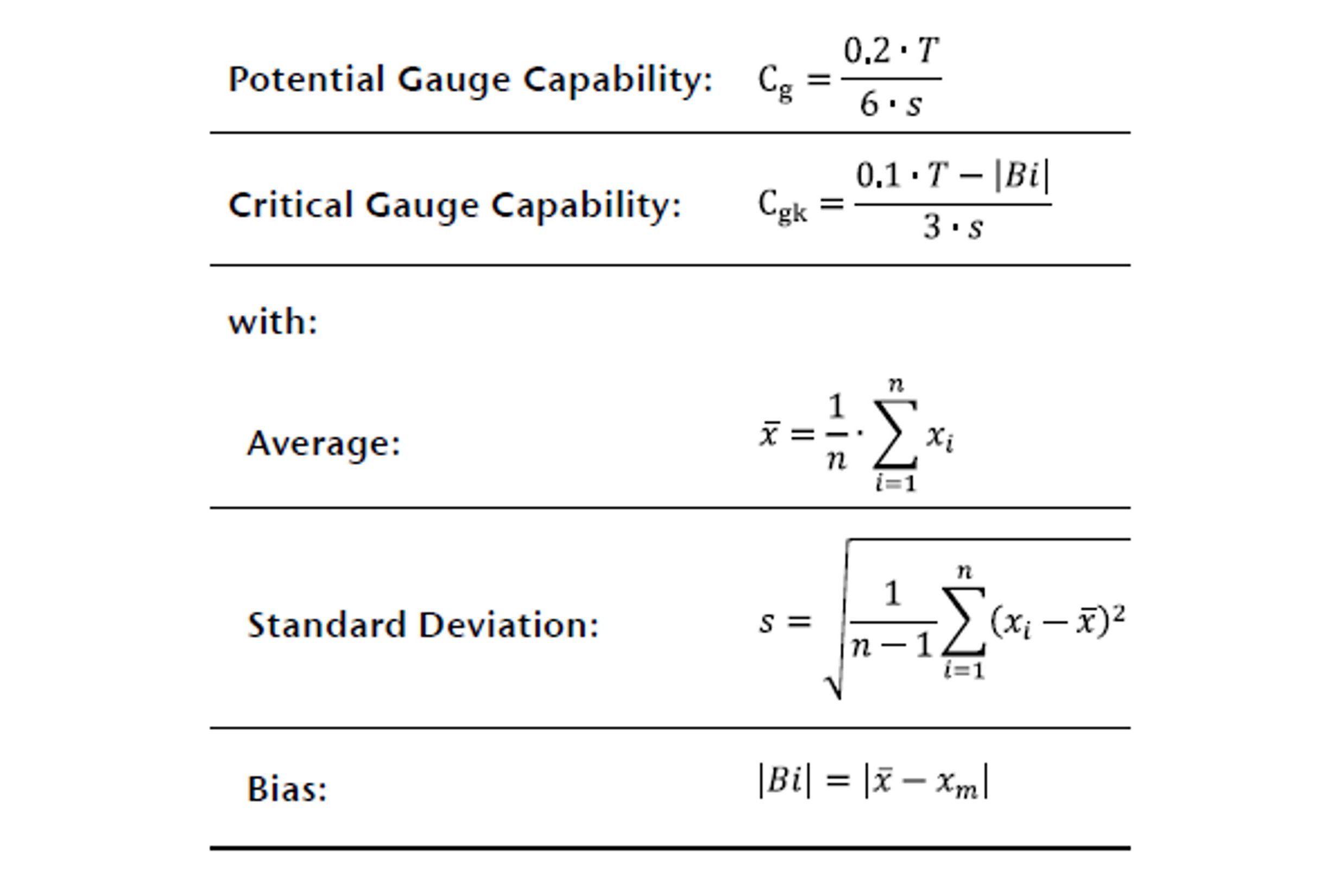

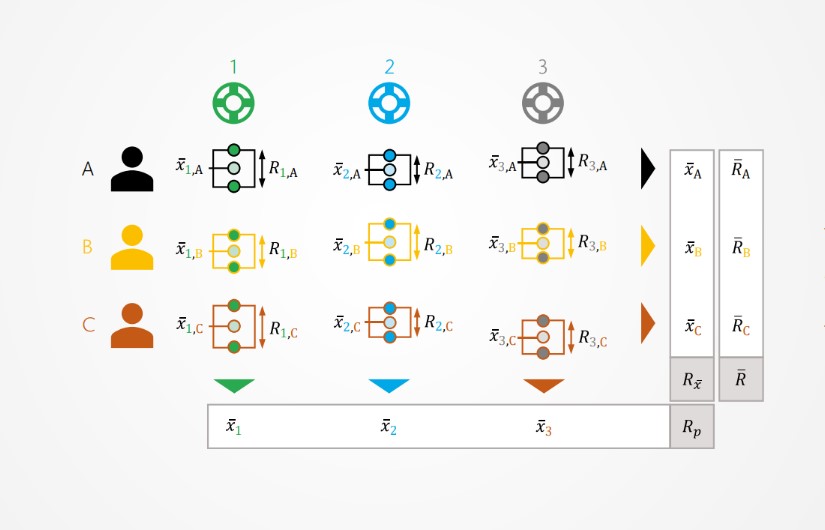

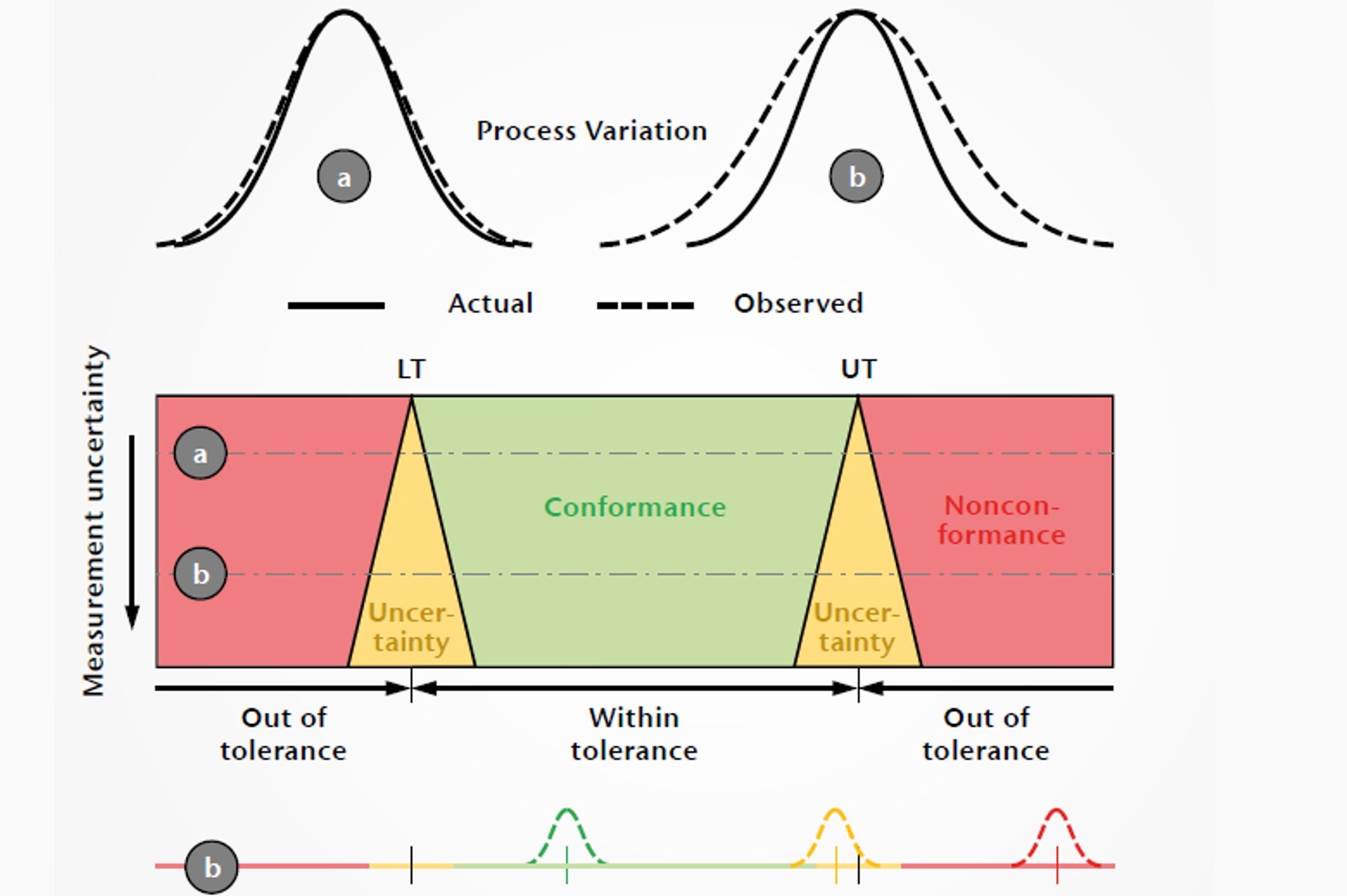

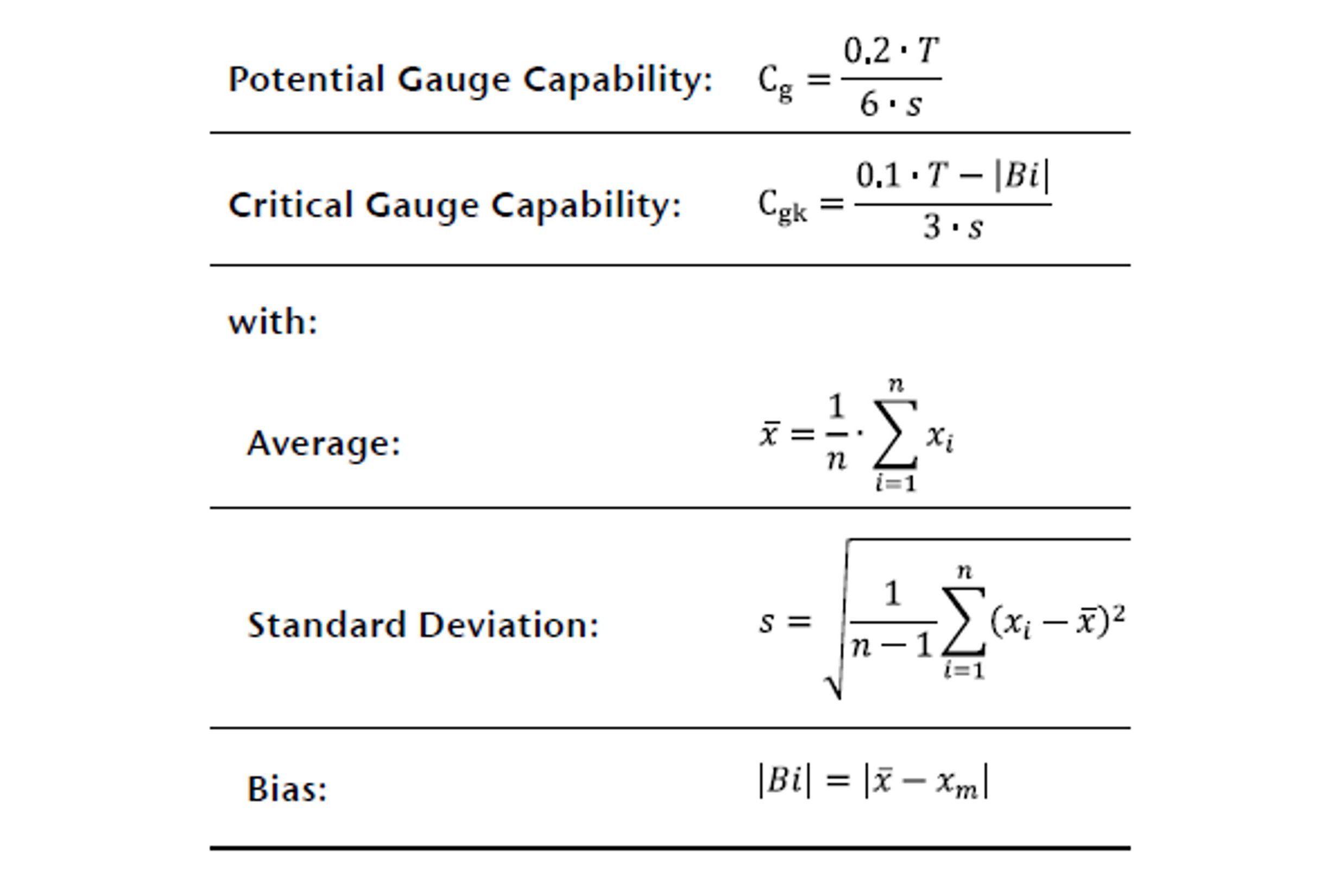

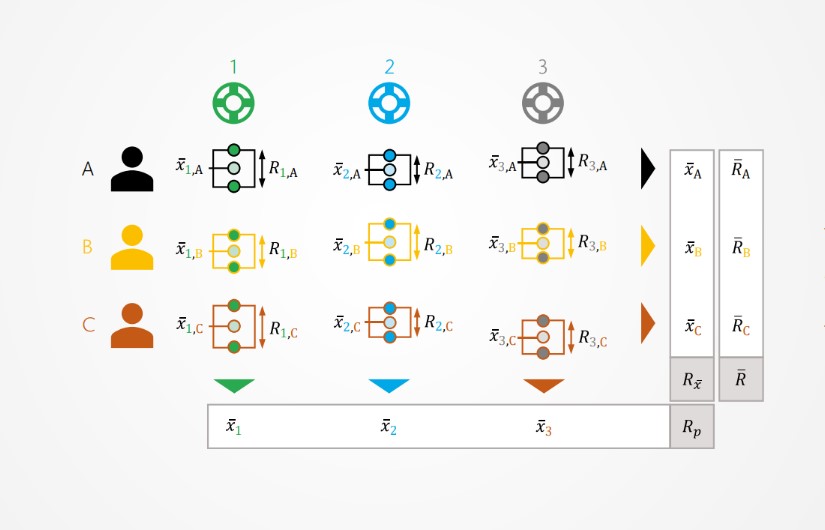

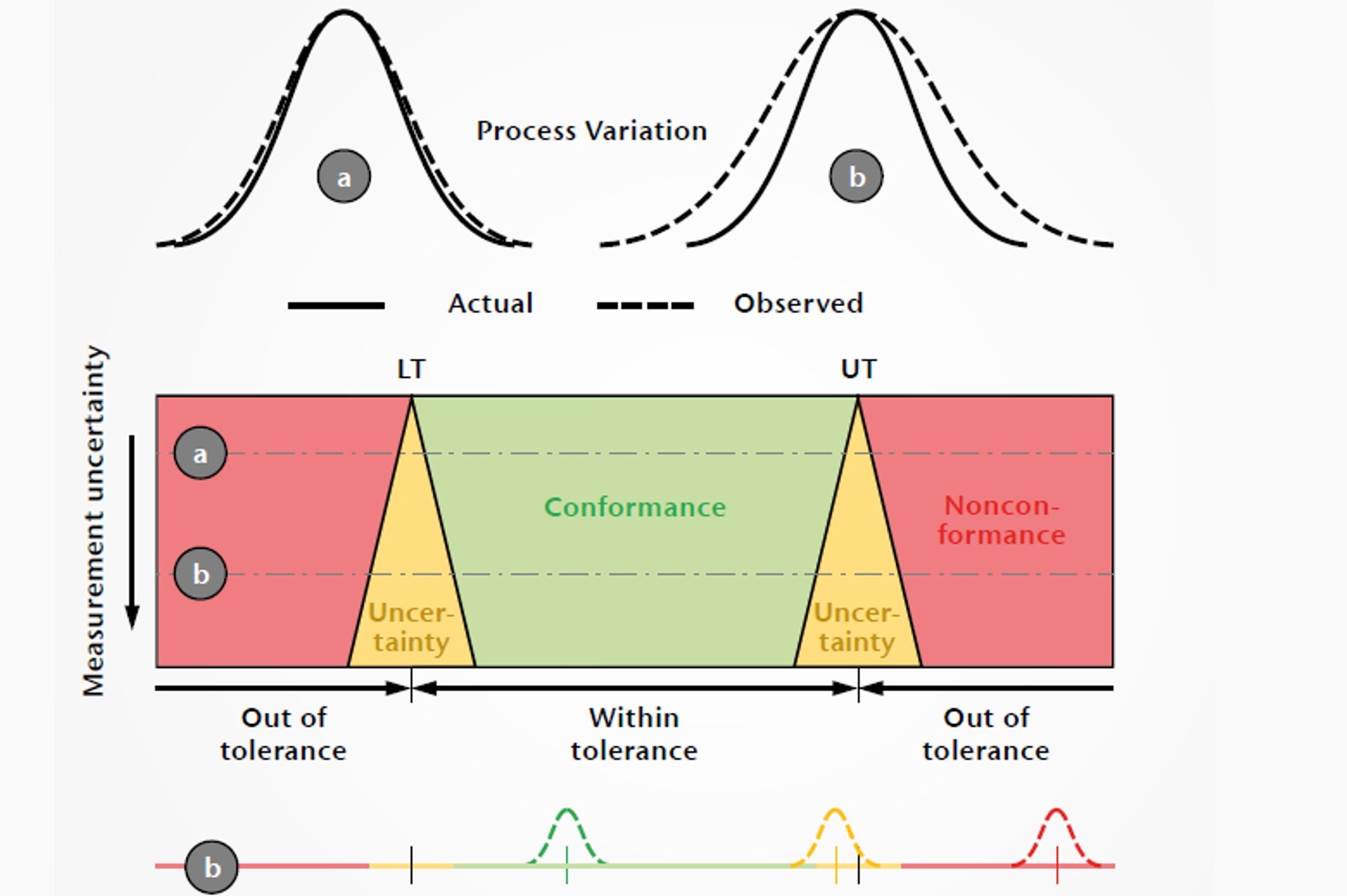

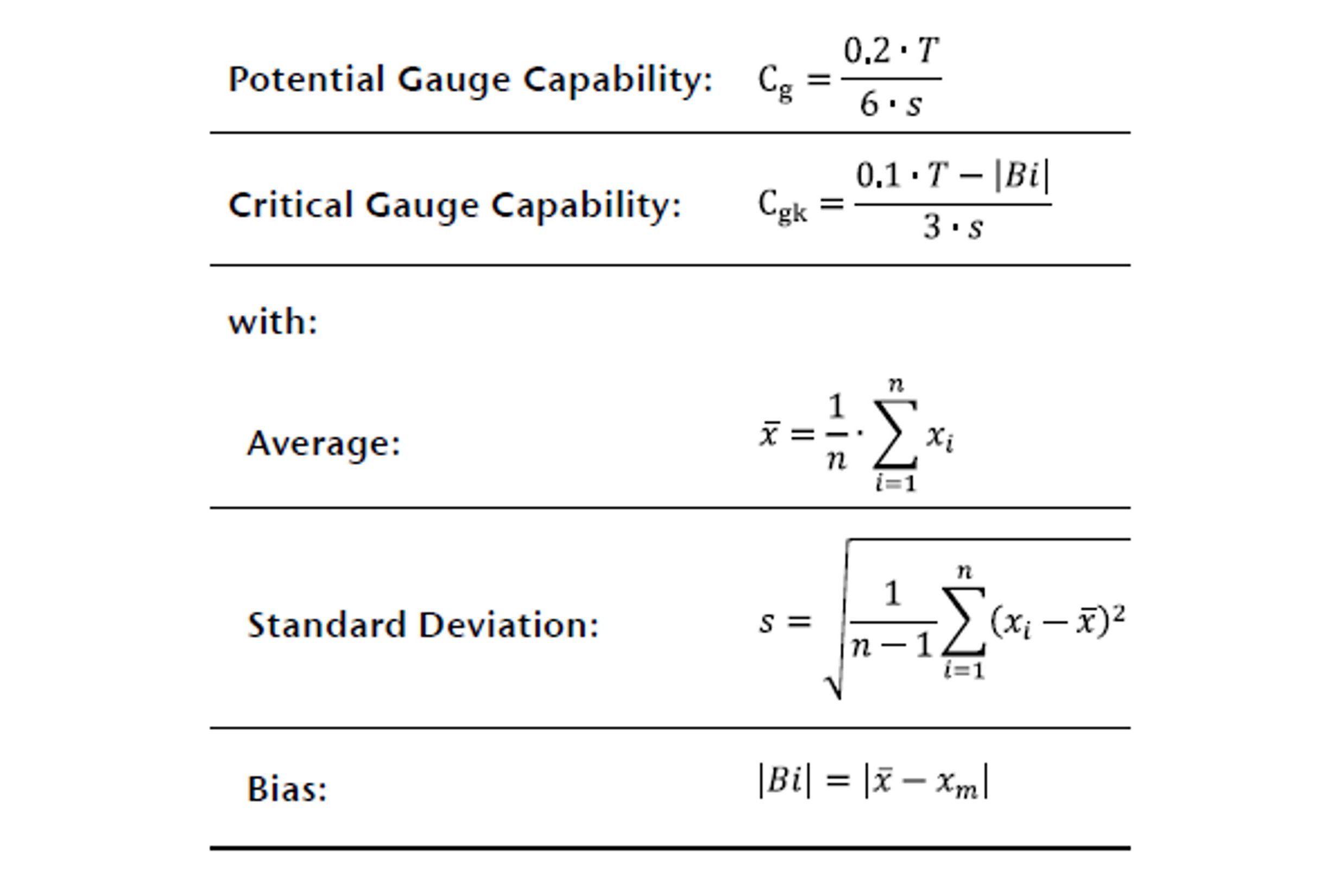

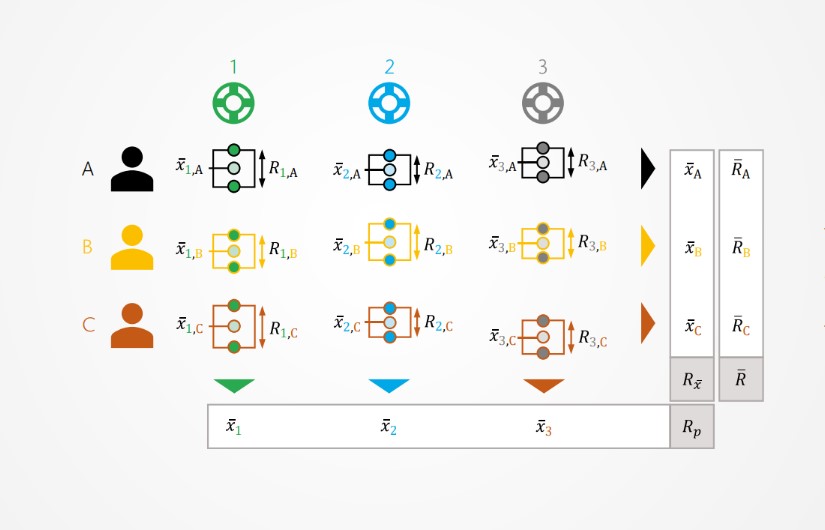

Free guide on how to: Measurement System Analysis

Every measurement - whether with tactile or optical surface profilers - is subject to uncertainty. The measured values obtained are the basis for quality-controlled production and are thus a key component of quality assurance. However, the correctness of any conclusion drawn by a measurement depends not only on the suitability of the parameter, but also on how accurately and how reliably the measured values reflect the real conditions. Only if the measured value can be determined with a sufficiently small uncertainty in relation to the tolerance of the characteristic, the measurement process is suitable for the inspection task. This paper describes approaches and helpful capability figures of Measurement System Analysis (MSA).

Read in the free guide how to deal with measurement uncertainty for your Quality Assurance!