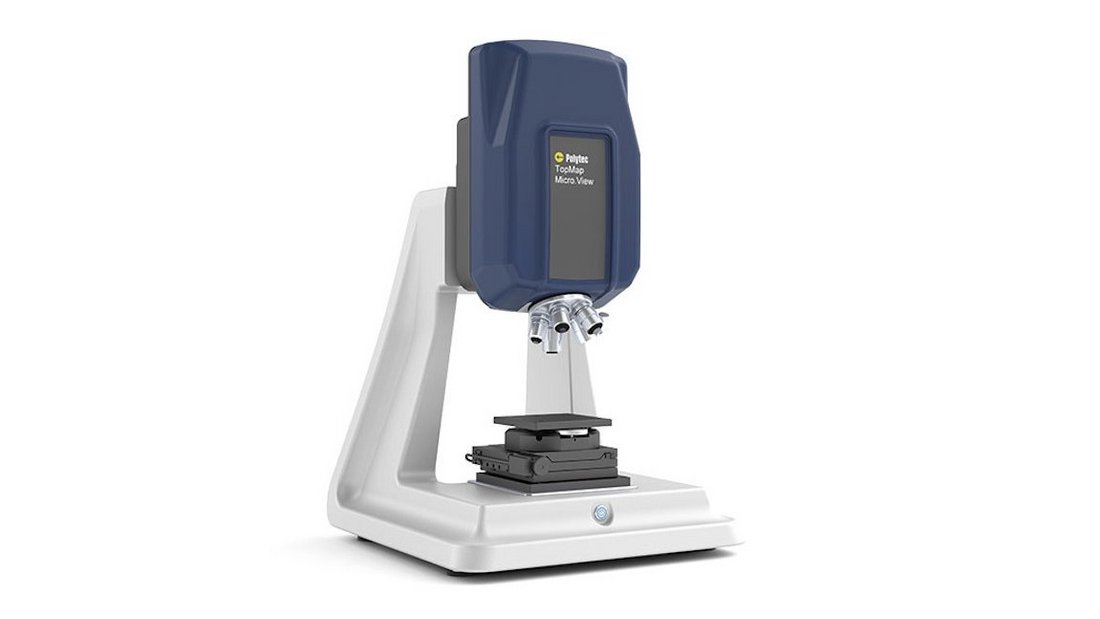

Watchmakers rely on CSI Coherence Scanning Interferometry

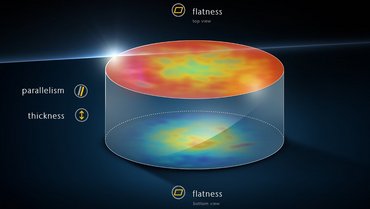

The surface quality of watch and clock parts depends on measurement precision and repeatability of CSI Coherence Scanning Interferometers (also known as white.light interferometers). Check geometrical tolerances on watch components, measuring form parameters like flatness, parallelism or step-height in watchmaking.

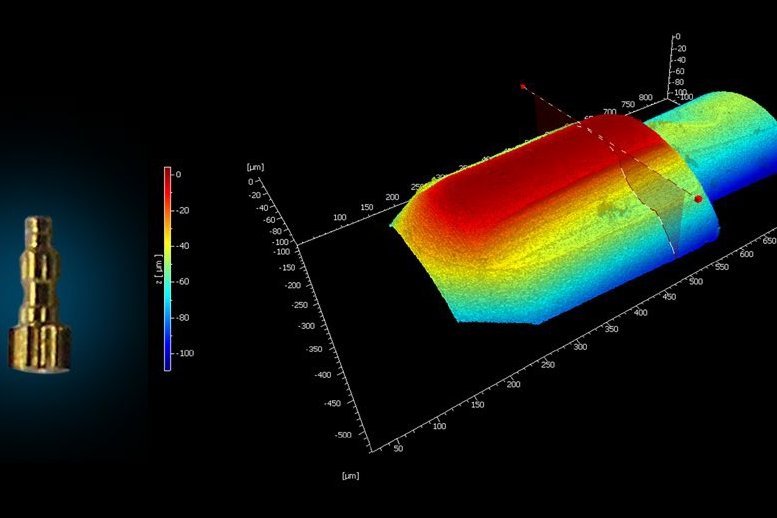

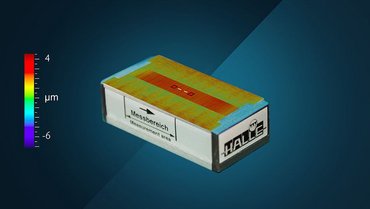

TopMap areal scanning white-light-interferometers deliver fast, complete and high resolution measurement data on micro parts. In contrast to other optical measurement technologies (fringe projection or focus variation), TopMap optical profilers measure reliably on both rough and optically smooth surfaces!