For surface quality inspections in production

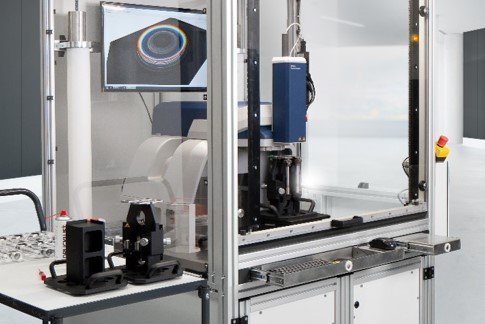

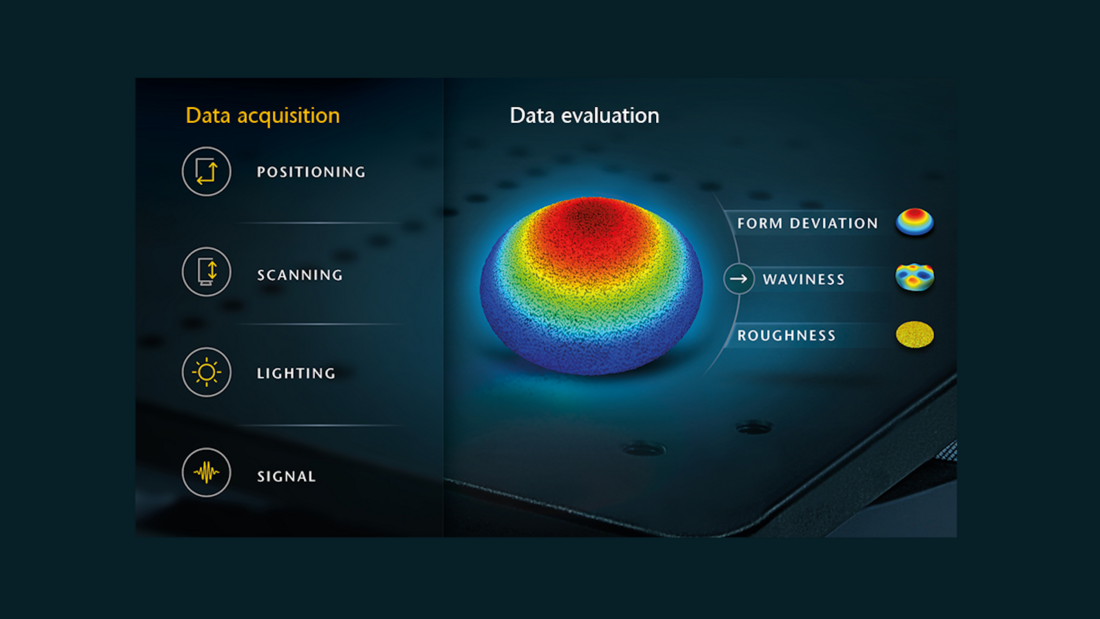

Industrial production benefits from tightly integrating surface metrology into the manufacturing process. With such tight integration, the inspection feedback allows immediate and cost-efficient control responses. Polytec’s TopMap surface metrology systems are designed to monitor manufacturing processes, assuring that production tolerances and process capabilities are met. The QC Package includes smart features and upgrade options for quality control tasks especially for real-life production testing. Learn more about how the QC Package supports 3D surface inspections especially in challenging production environments.

Highlights

- Avoid false rejects in challenging production environments with the innovative ECT Environmental Compensation Technology

- Time-saving motorized Tip-Tilt Unit for precise sample positioning

- Simple one-click solutions avoid operator failures and save time

- Achieve and monitor global quality standards

- Protect measurements in rough production environments

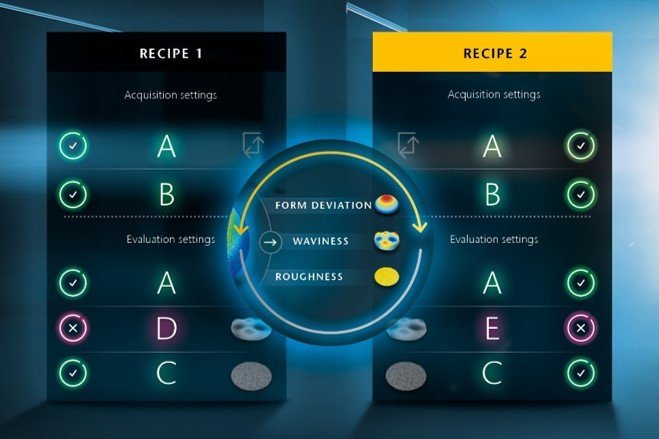

- Simplified loading of settings saves time

- Ask for customized software to meet your individual needs

Quality control with TopMap surface metrology - control your process with the QC Package

Innovative ECT Environmental Compensation Technology

Rejecting only real defects and saving money by reliably distinguishing pass and fail wihtin the production process is what the QC Verifier does best. Real-life production environments can be tough and challenging, when noise, vibration and uncontrolled movement make it difficult to measure precisely on the factory floor. This can lead to false rejects. Here, the QC Verifier comes into play with its innovative ECT Environmental Compensation Technology that isolates precision measurements for quality control and effectively protects from external influences.