Validating models the easy and efficient way

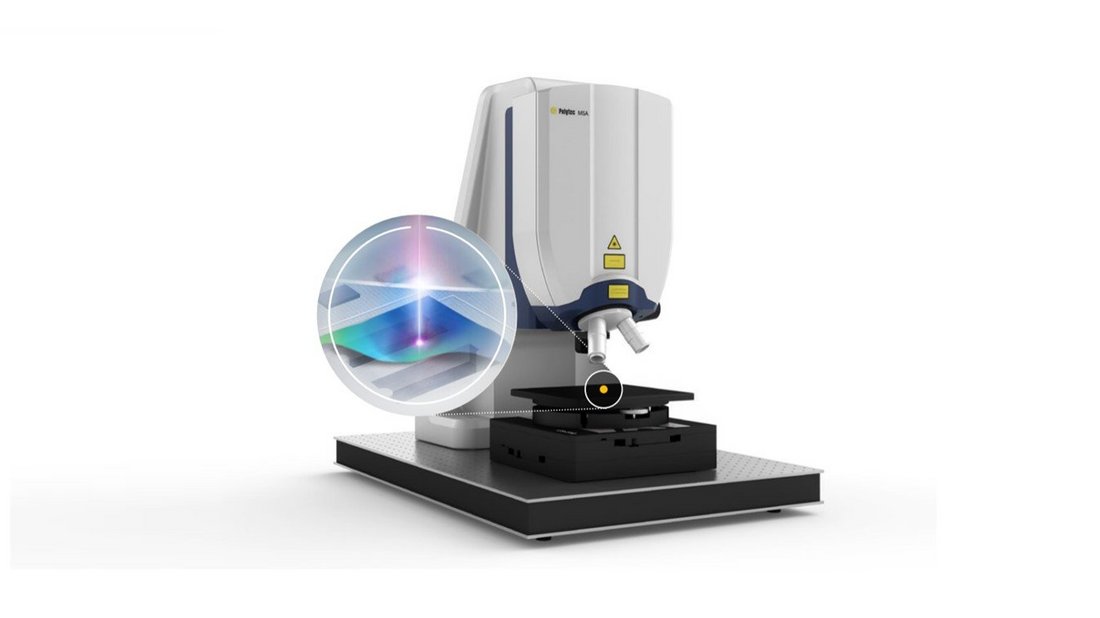

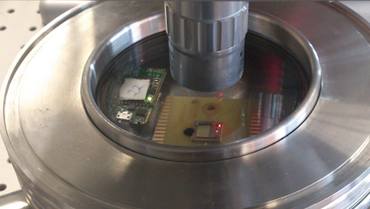

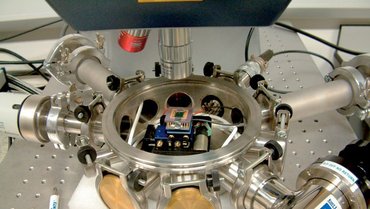

It is hardly possible to imagine developing MEMS components without computer simulation. FE simulation models have to be tested and refined through comparisons with experimental data. Non-contact, optical measurement methods are essential to characterizing the mechanical properties with maximum precision. Laser Doppler vibrometers from Polytec have proven to be the perfect technique for quickly, easily and optically detecting the mechanical movement of structures within MEMS components and correlating the modeled behavior with the measurement data. This can be done on a single die or on wafer level by easy integration with any MEMS Wafer Probe Stations.

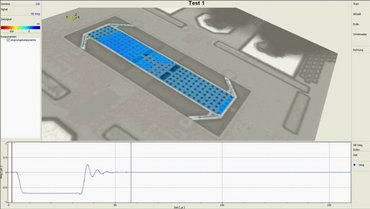

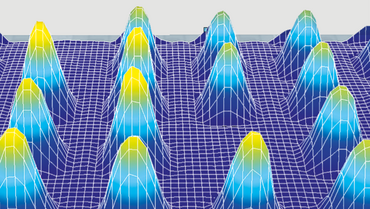

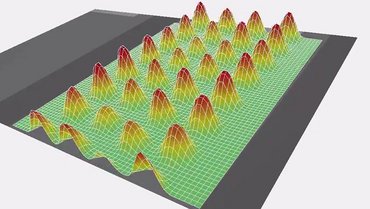

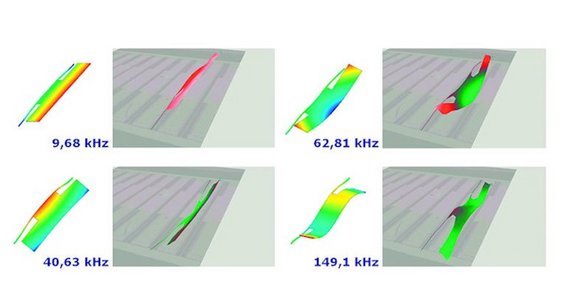

Model validation of a micro mirror array

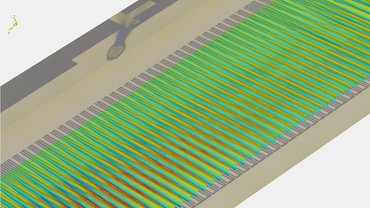

The broadband real time measurement, combined with the Polytec vibrometers’ excellent amplitude resolution, allows you to easily and efficiently determine the transfer functions for model validation. The figure shows the comparison between the FEM model calculation and the vibrometer measurement on a MEMS micro mirror array.