Experimental modal analysis simplified

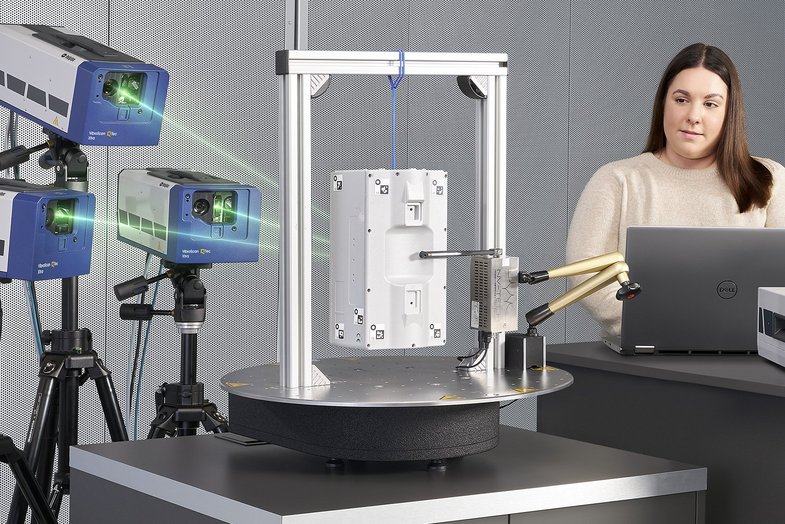

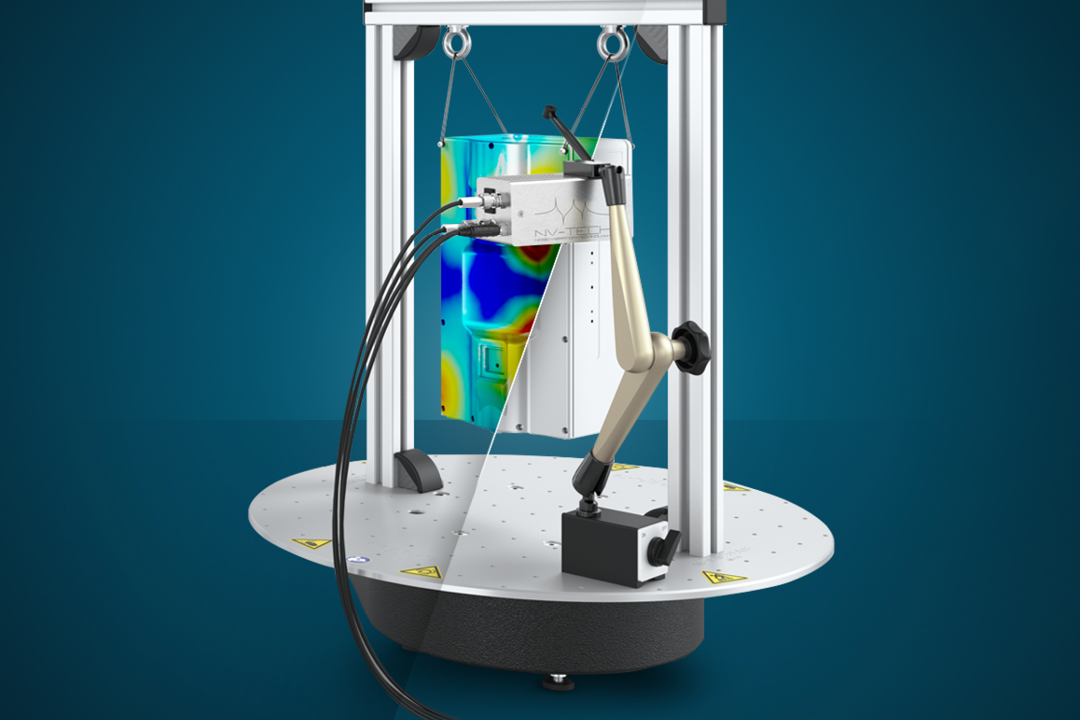

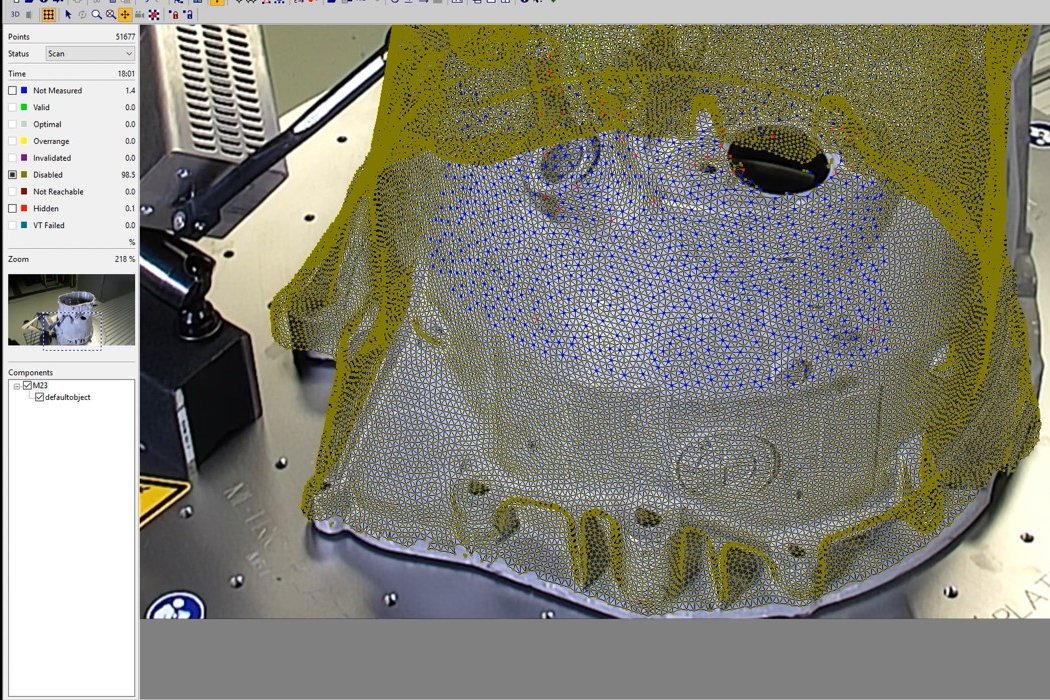

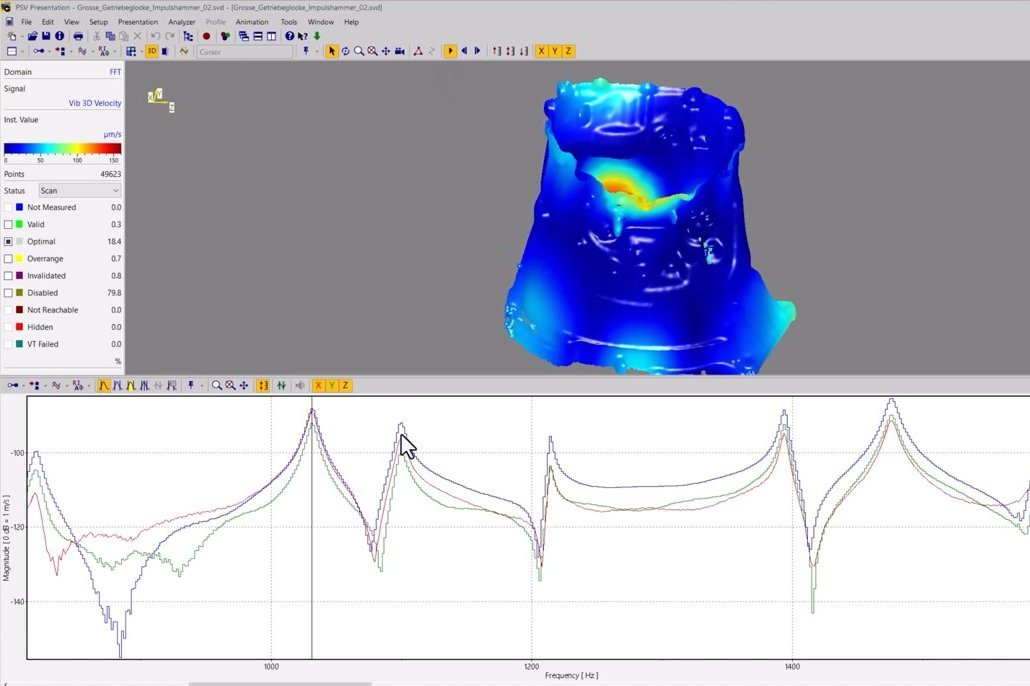

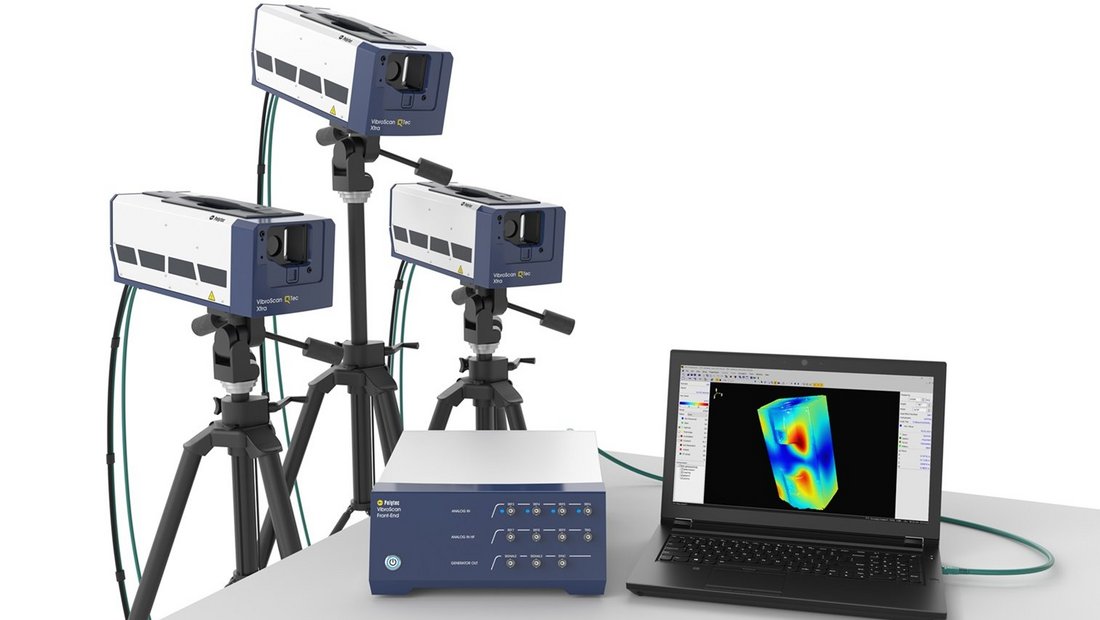

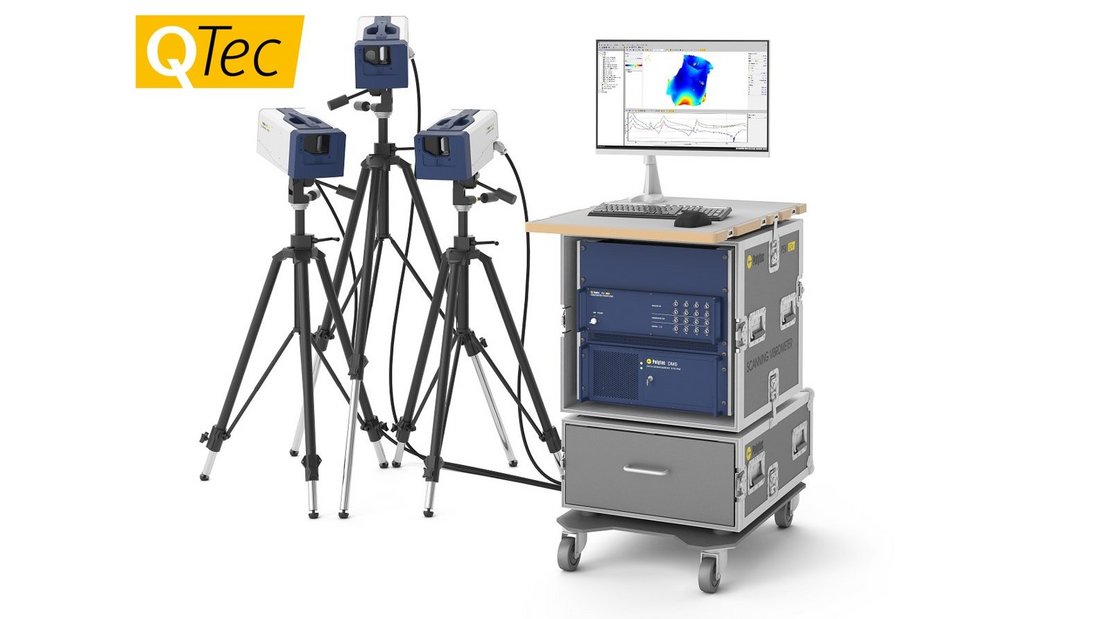

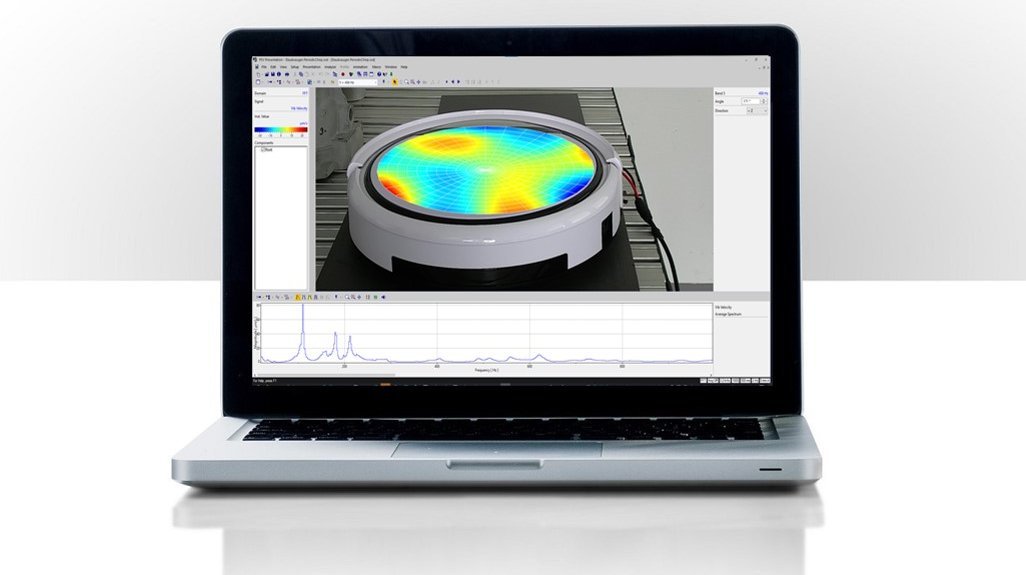

RoboVib® Bench enables automated and full-body experimental modal analysis using Polytec’s optical 3D scanning laser Vibrometers. Its easy to set-up hardware and software integrates seamlessly into the Polytec scanning vibration measurement workflow and saves time by automatically repositioning the devices-under-test (DUT) instead of a manual and tedious relocation of the sensor setup. 360° measurements of the DUT are as easy as a measurement from just one side.

Highlights

- RoboVib® Bench automated modal test station

- Integrates into the CAE workflow

- Creates full-body 3D vibration data set

- Small footprint for lab use

- Accepts part up to 50 kg (110 lb)

- Interfaces with PSV software

- Ready to use – no installation