We're sorry...

The webinar has already taken place.

Attend this webinar and learn about...

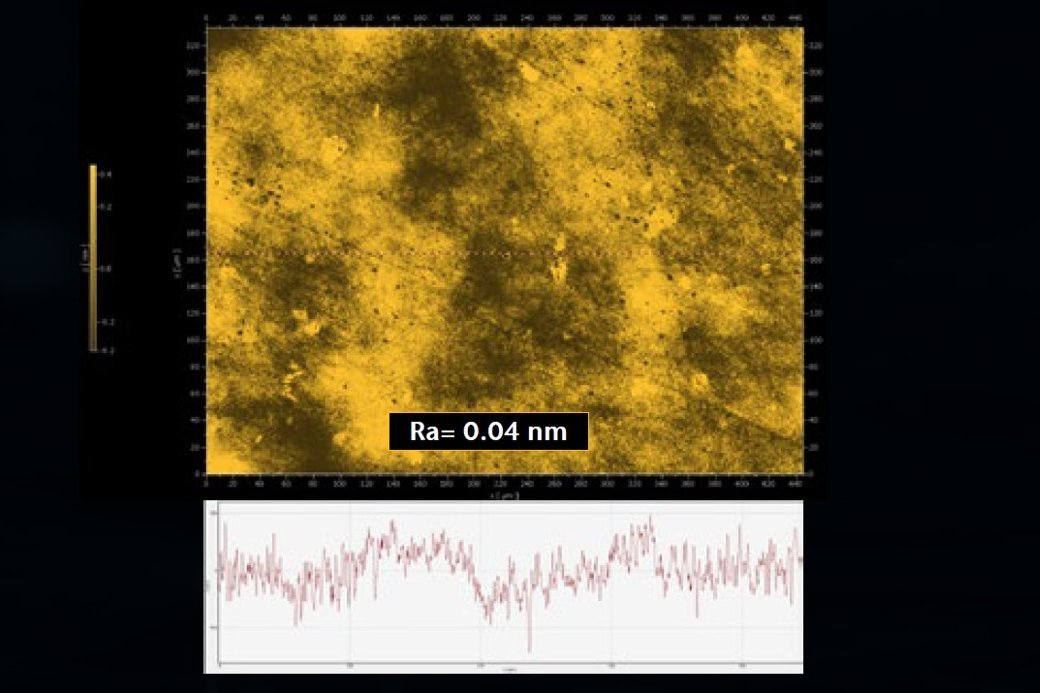

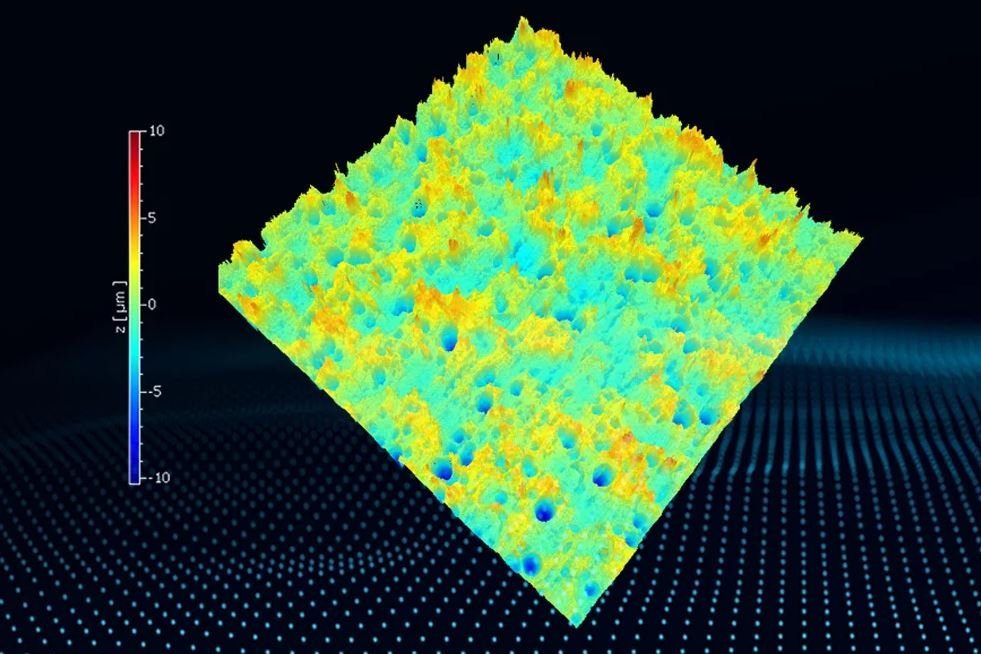

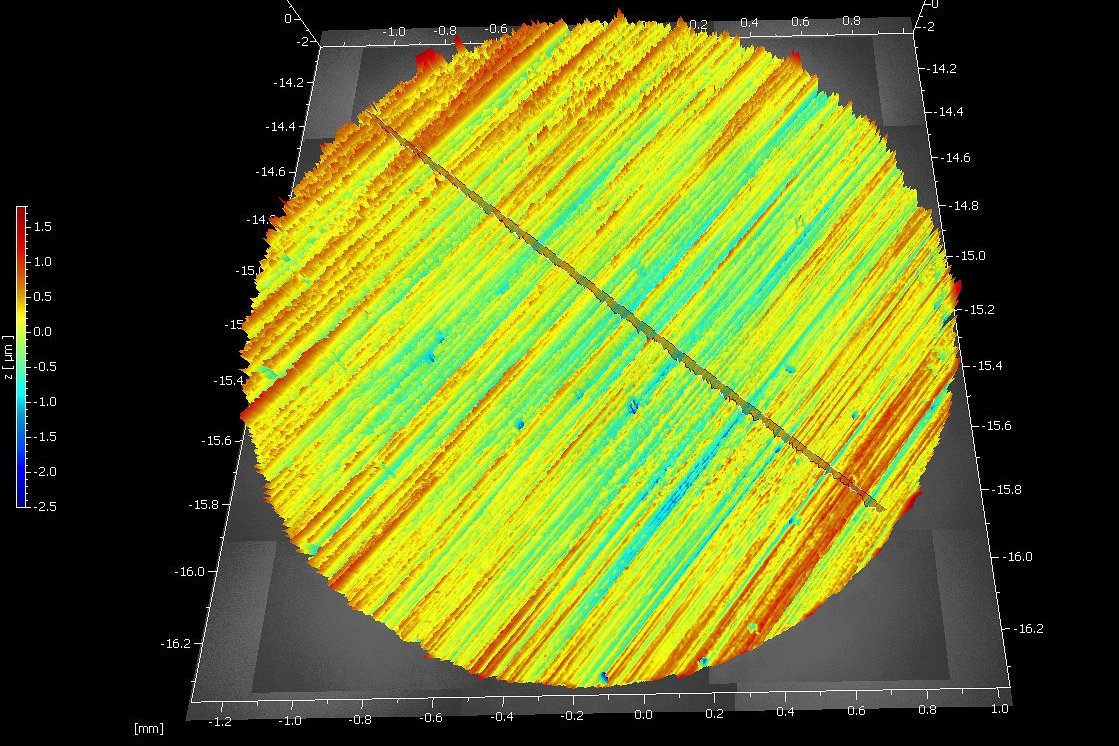

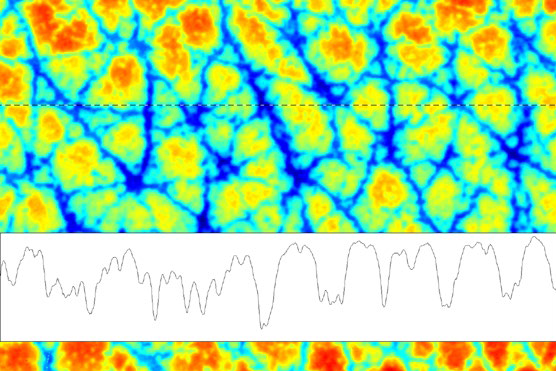

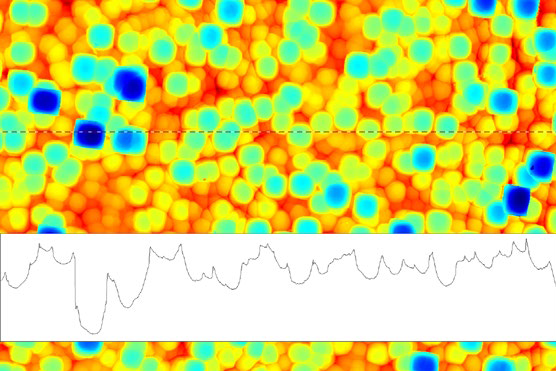

- ... the basic concept of measuring roughness in 2D + 3D

- ... understand and apply measurement settings the right way

- ... orientation in standardization and what changes with ISO 21920

- ... where optical areal profiling speeds up while revealing more insights of your workpiece

Voices of Participants

Really good seminar [...], it clearly dealt with how to define and measure roughness.

I learned a lot. many thanks to the speaker.

The orientation about the new ISO standard helps, while we still measure 2D instead of 3D. thank you very much!

Meet up with Joe

Joe Armstrong, your speaker

Educated in Bedfordshire, England, Joe Armstrong qualified in computer electrical engineering before starting an over 30 years long carreer in the optical technology and metrology business. Experienced in laser technology, optics and optical metrology for both dynamic (vibrations) and static surface topography, Joe now is one of our international PolyXperts and enthusiasts of our Surface Metrology group at Polytec Headquarters in Germany.

How to access the free webinar

1. Fill out the form and click on “register”.

2. Check your e-mail and confirm your e-mail address.

3. You will receive an e-mail from us with the webinar link.

Can't attend the webinar? No problem!

Register anyway and we will send you a recording afterwards.