Mass flow control and how to improve the rolling process

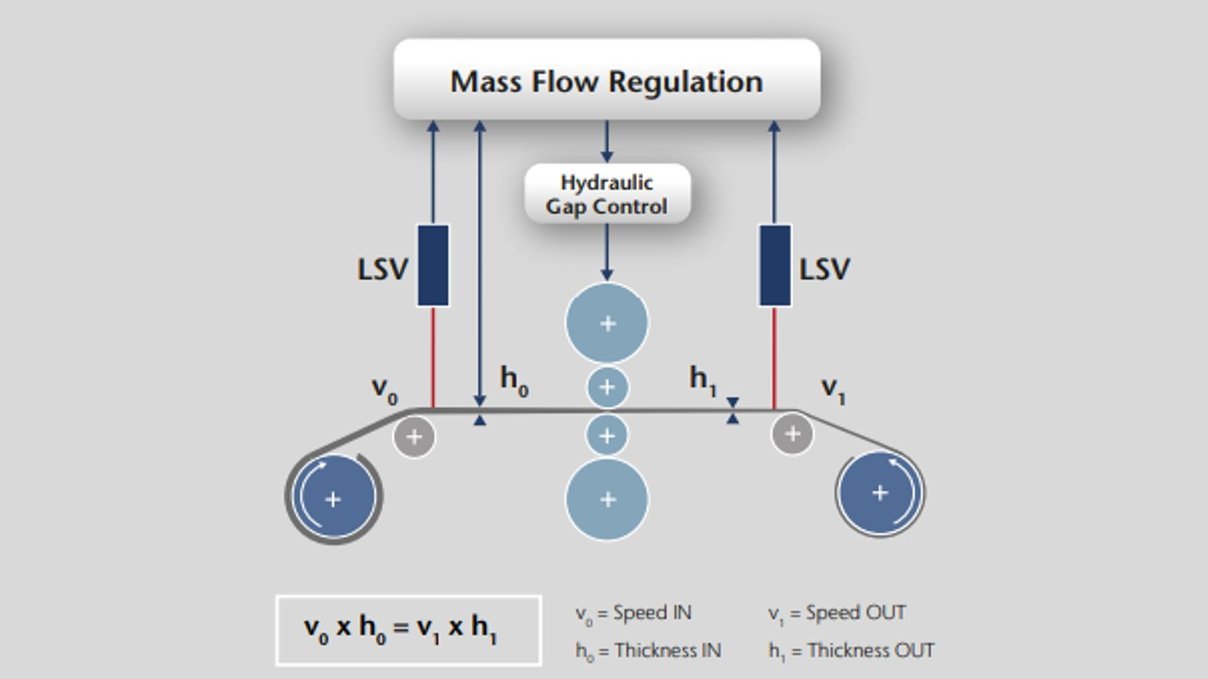

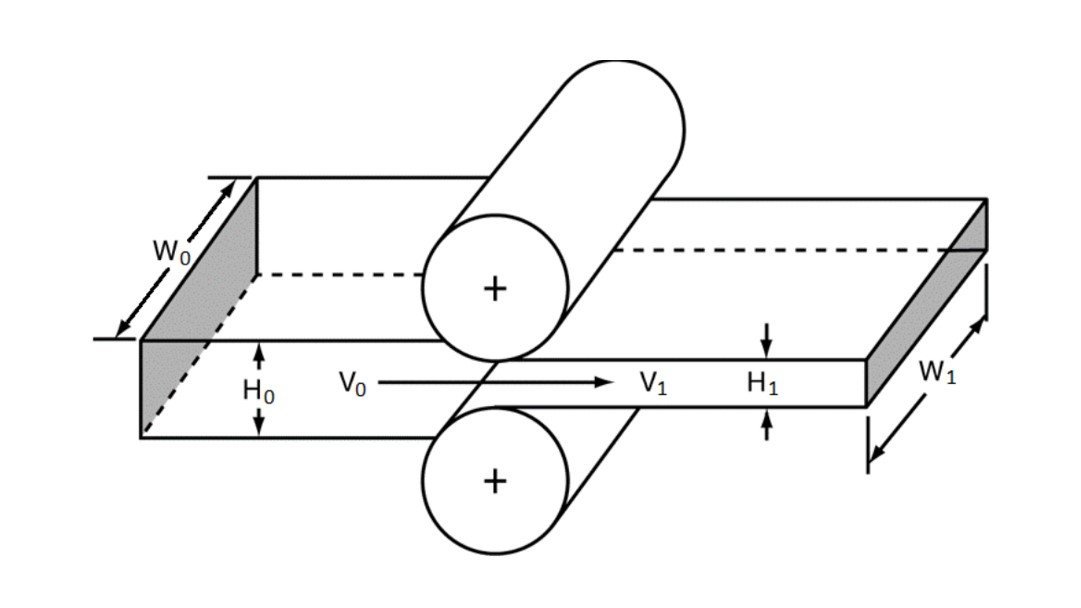

Mass flow control is essential for processing metals. Controlling mass flow process means controlling the width of the roll gap so that the material thickness of the final product remains as constant as possible. If the thickness before the roll stand and the velocity before and after the roll stand are known, the roll gap, which determines the thickness of the rolled product, can be adjusted in accordance with the desired conditions.

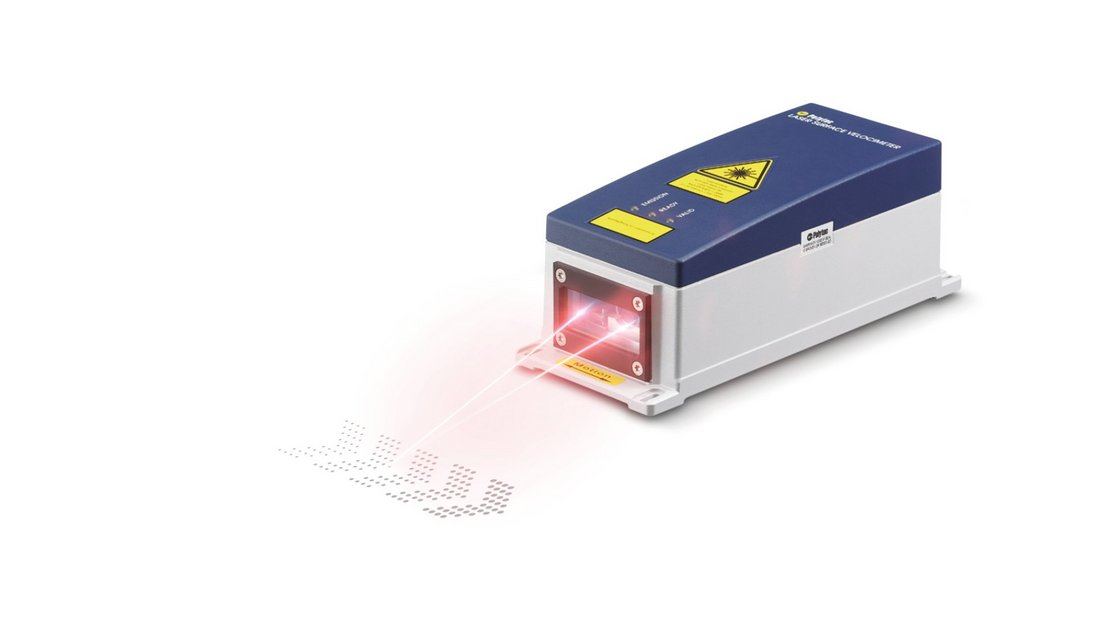

Optical sensors from Polytec measure length and process speed without contact but with interferometric precision, while avoiding slippage, wear and uncertainty. They offer digital and analog output signals for the PLC just like any classic encoder and are easy to integrate. Contact us and we will make a live demo of what is possible!

Measure roll gap width, skin-pass degree and strip speed in cold rolling with laser precision?

Mass flow control via roll gap and strip thickness measurement

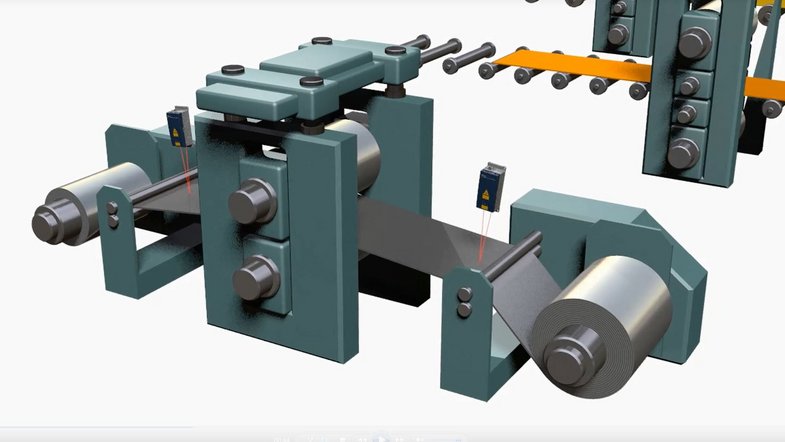

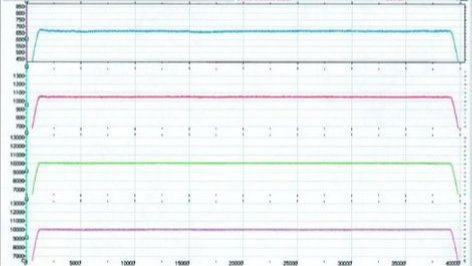

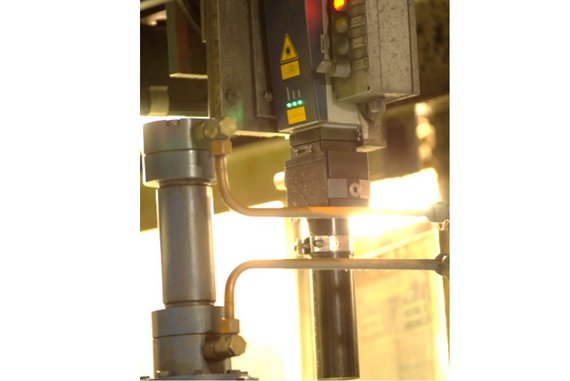

The strip thickness is measured using C-frames with an integrated, compact LSV Laser Surface Velocimeter, measuring the velocities upstream and downstream of the roll stand. Because the speed measurement is extremely accurate, you can monitor and control the roll gap more precisely using the LSV and thereby obtain better compliance with the thickness specification of the end product. The result is increased quality and, consequently, increased product output.

Mass flow control using laser sensors

LSV Laser Surface Velocimeters from Polytec are laser speed sensors that measure on almost any surface, even on contaminated surfaces and in harsh environments of rolling mills. The non-contact measuring technique efficiently eliminates slippage, wear while providing a laser precise and reliable process and mass flow control without influencing the surface of the rolled goods.

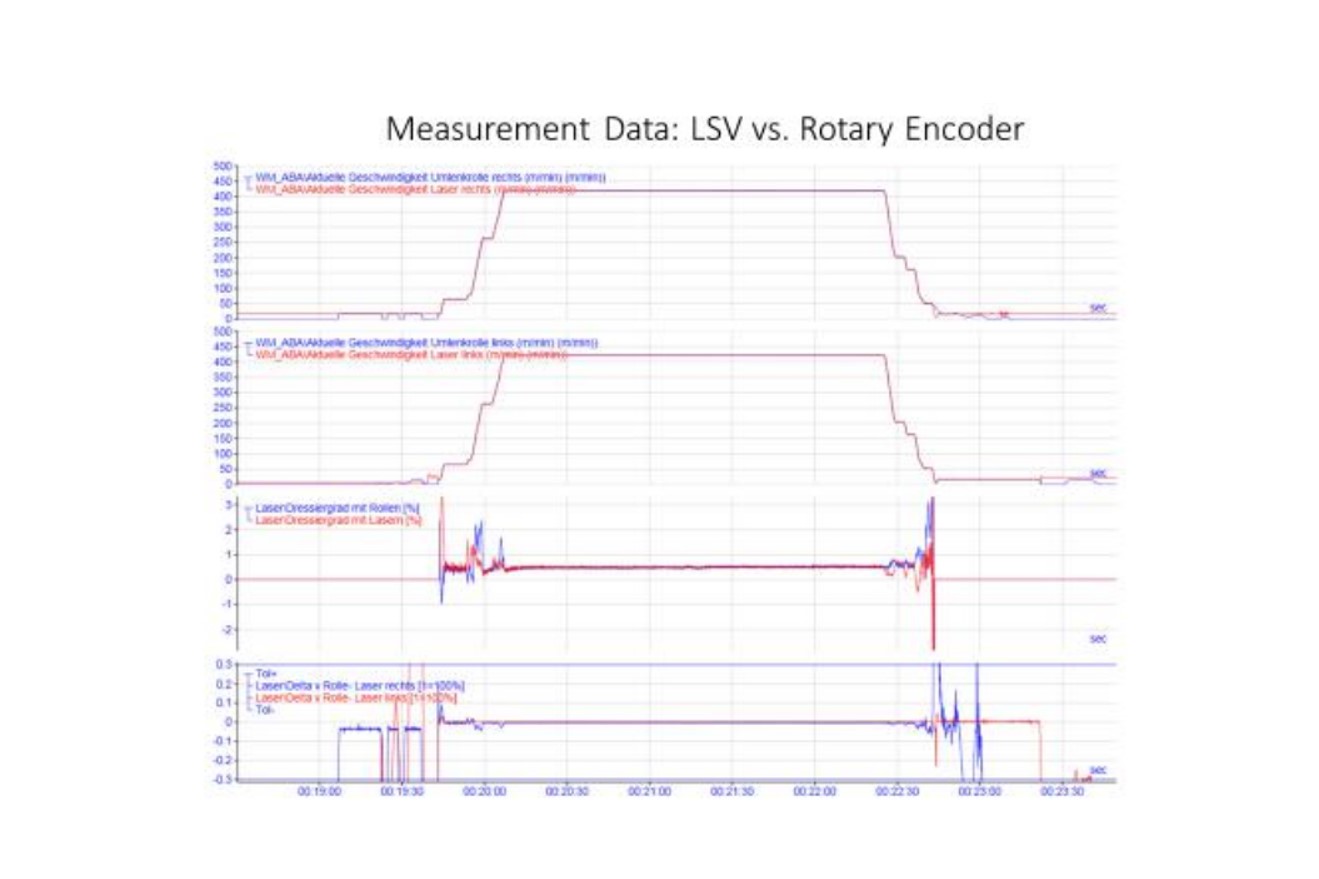

Controlling mass flow by skin-pass and stretch degree measurement

The skin-pass degree in cold strip skin-pass rolling is determined by the difference in strip velocity at the input and output of the roll stand, which in the past has been measured mechanically, usually by using tachometer generators. Using two Polytec LSV laser sensors prevents the occurrence of measuring errors owing to slippage and wear and the skin-pass degree measured can directly be used as a reliable parameter for adjusting the rolls in mass flow control. Major stainless steel manufacturers all around the world confirmed optimizing the measuring precision up to ± 0.02 % of their skin-pass degree measurement using LSV Laser Surface Velocimeters from Polytec.