Single-point vibrometers

Single-point vibrometers

Single-point laser Doppler vibrometers measure transfer functions, amplitudes and resonance frequencies without contact in a non-intrusive way thanks to the simple “point and shoot” principle. Single-point vibrometers are laser vibration sensors that measure object vibrations in the direction of the laser beam (out-of-plane motions). From modular concepts to robust industrial vibrometers or compact designs – Polytec will always provide you with the ideal measuerement tool to solve your individual vibration measurement task.

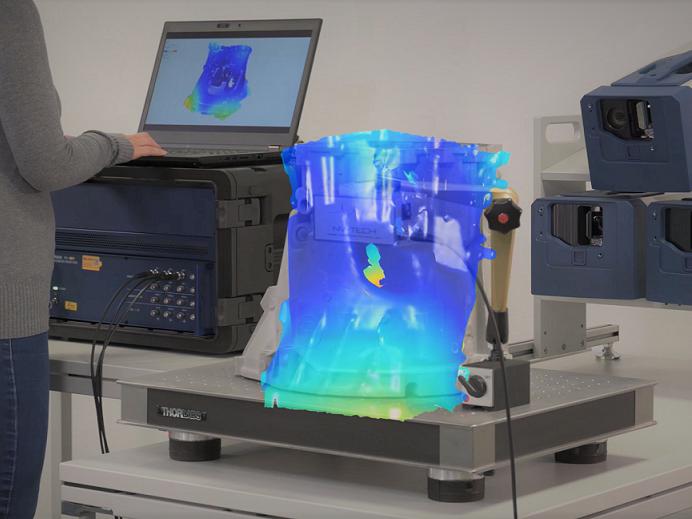

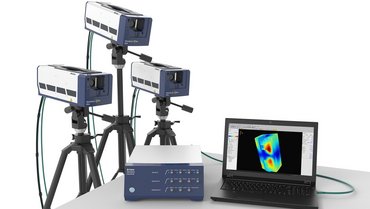

Full-field vibrometers

Full-field vibrometers

Full-field vibrometer are vibration measurement systems that allow engineers to conduct areal deflection shape measurements as fundament for validating simulation models and identifying vibration hotspots. They keep the focus firmly on complex vibration behaviour over the entire surface. Polytec’s product range includes everything from scanning vibrometers for stationary processes to multipoint vibrometers (that measure in parallel) for non-stationary and transient processes.

Microscope-based vibrometers

Microscope-based vibrometers

Inspired by the rapid further development of microelectromechanical systems and MEMS, Polytec presents this highly innovative product line of microscope-based measurement systems. MSA Micro System Analyzers from Polytec validate dynamics and topography of microsystems reliably with utmost precision.

Special-application vibrometers

Special-application vibrometers

Special testing needs may require special measurement tools. Whether measuring ultrasonic applications in the very high frequency range, or rotational vibrations on rotating structures, or in-plane vibrations measured perpendicular to the measurement beam – there is a Polytec vibrometer ot provide the perfect solution.

Onsite & in-house testing service

Testing services & rentals

We offer a wide range of testing services done in your facility or in our fully equipped labs for vibration testing, surface metrology, acoustics, speed, and chemical analysis. In addition, all of our products are available for short and long term rentals and leasing.

Unlock the full potential of your project with Polytec's expert-driven testing services and extensive equipment range. Whether you are delving into vibration testing, surface metrology, acoustics, length & speed measurement, or chemical analysis, our team is equipped to assist. Utilize our advanced technology and the expertise of our professionals to ensure precise and reliable results. With Polytec, you gain access to a world of measurement solutions, all tailored to meet the exact needs of your project. Let us be your trusted partner in navigating the complexities of testing and analysis, and watch as we transform challenges into opportunities for innovation.

PolyLab educational program

Do you want to prepare your students for the cutting-edge technology they will encounter in the industry? While many engineering disciplines involve the study of vibro-acoustics, the cost constraints mean that numerous school labs today are equipped only with basic accelerometers and microphones. Our PolyLab & PolyLab+ educational programs aim to bridge this gap, offering students the opportunity to familiarize themselves with state-of-the-art technology widely used in various industries.

PolyLab & PolyLab+ programs employ technology that goes beyond the limitations of traditional transducers. Vibrometers are indispensable for measuring on lightweight, very small structures, high-temperature surfaces, and underwater tests. Additionally, they can measure sub-picometer amplitudes and frequencies as high as 8 GHz.

Contact us to assess whether your institution qualifies for PolyLab or PolyLab+, and you may be eligible to receive free vibrometer loaners for educational purposes, ranging from 6 weeks up to 2 years.

Learn more about our laser solutions for research & production today

Optical measurement technology

Polytec offers laser vibrometers for research, development, production, and long-term monitoring. These systems analyze samples of all sizes, from car bodies and aerospace parts to micron-sized MEMS and biomedical specimens. Non-contact vibrometry benefits fields like engineering, biology, and medicine, handling challenges such as hot surfaces, rotating parts, and ultrasonic frequencies. Explore your options today.

Aerospace

Aerospace

Both turbine durability validation and the development of new NDT methods or a classic modal test will likewise benefit from vibration sensors that supply reliable results in a non-intrusive way. These can even be achieved in a vacuum, over long distances and under all temperature conditions. You can determine transfer functions, deflection shapes and strain distribution quickly and without any need for the time-consuming process of instrumentation.

Application examples include:

- Electronic Components Testing

- Model Validation

- Takeoff Stress Testing

- NDT

- Turbine Testing

Acoustics & ultrasonics

Acoustics & ultrasonics

Vibrometers are indispensable tools for you when you’re designing loudspeakers and identifying disturbing membrane resonances. Vibrometer measurements provide an experimental basis for challenging acoustic problems, such as predicting the structural-acoustic response, acoustic imaging, anti-sound and much more besides. Laser vibrometer measurements also prove beneficial in microphone, cell phone and hearing aid development.

Application examples include:

- Industrial ultrasonic methods

- Loudspeakers & musical instruments analysis

- Medical ultrasonic design & development

- Ultrasonic imaging

- Ultrasonic motors

Automotive

Automotive

In the automotive industry, technical surfaces tip the scales when it comes to high-precision mechanics and their performance. The dimensional tolerance has a decisive influence on a product’s fuel and energy efficiency, eco-friendliness and durability.

From sealing surfaces, to the drivetrain and shock absorbers and to injection systems, there are a multitude of applications “being put to the test”. Absolute precision when contactlessly determining flatness, parallelism, form parameters, surface parameters, heights and steps is vitally important. And what should you use to ensure this? The surface measurement systems from Polytec, of course!

Application examples include:

- Drivetrain

- Sealing Surfaces

- Fuel Injection Systems

- Shock Absorbers

- Pass / Fail Analysis

- Tribology

Biology & medicine

Biology & medicine

The demands placed on instruments that are used in biology or medicine, and in particular that come into contact with the human body, are extremely high. A great deal of importance is attached to the surface quality of such equipment, which includes dental implants and artificial hip joints. There are also high expectations of both the reliable functioning and a long service life of such equipment – and these represent the biggest challenges of all.

Application examples include:

- Lab-on-a-chip

- Fill level

- Implants

Data storage

Data storage

Hard disk drives are everywhere, and everyone is reliant on them working reliably and perfectly. To guarantee these essential aspects, manufacturers and their suppliers devote much of their energies to development and manufacturing.

Polytec gives them a helping hand in this regard. Whether you’re dealing with hard drive bearings, hard drive disks or write / read heads, Polytec’s range of surface metrology products help you to boost reliability in your production processes.

Application examples include:

- Bearings

- Disc flatness

- Read/write head

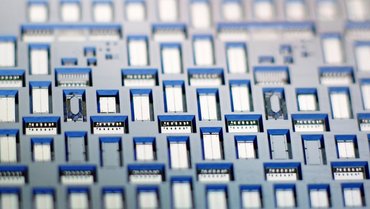

Electronics, semiconductors, solar

Electronics, semiconductors, solar

You can ideally adapt Polytec’s versatile solutions in the semiconductor industry for your applications in the electronics and solar technology industries. In the field of software, for example, you can do so by utilizing application-specific user interfaces for the OK / NOK analysis.

Polytec offers you solutions to check electronic contacts – both for analyzing the height of BGAs or “solder bumps” and for analyzing the co-planarity of IC pins. You’ll also find the right systems for packaging high-power laser diodes at Polytec.

Application examples include:

- Electronic contacts

- High power laser diodes

- Mobile devices

- Pass / fail analysis

- Solder bumps

Industrial quality control

Industrial quality control

The laser vibrometers are robust and reliable sensors for complete parts control in final production testing. The major benefits for you lie in the fact that they are non-contact, are set up to suit industrial processes and can be put to flexible use. Polytec vibration sensors are compatible and easy to integrate into complete test stations for production testing. We can work with your integrators, or provide a fully turn-key solution for reliable pass-fail decisions and classification of parts.

Application examples include:

- Automated noise test stations for actuators & drives

- White goods testing

- Engine cold test

- Injection valves

- Medical device manufacturing

Material research and testing

Material research and testing

Round the world, scientists at hundreds of universities and research centers for engineering, materials research, machine construction and many other specialist fields place their trust in instruments from Polytec. Laser vibrometry has proven its worth as an ideal tool for materials investigations – both for the measurement of structural dynamics and for the non-destructive detection and prevention of signs of fatigue. There are a wealth of applications in functional and long-term structural monitoring and in geological issues.

Application examples include:

- Fatigue testing

- Material testing

- Drop testing

- Surface waves

Microtechnology & Nanotechnology

Microtechnology & nanotechnology

Using the versatile surface measurement systems from Polytec, you can complete your micro and nano technology tasks reliably, quickly and with a high level of precision.You can eject channel depths on your lab-on-a-chip, determine the step height on MEMS packaging, establish how flat pressure sensors are and analyze MEMS using surface parameters. Even performing dynamic out-of-plane and in-plane measurements on RF filters to determine MHz resonance frequencies will be a simple task for you now – thanks to Polytec’s Micro System Analyzer series.

Application examples include:

- Lab-on-a-chip

- MEMS

- Vertical interconnect access (VIA)

Why use Polytec vibrometers?

Ease of Use

Polytec vibrometers are easy to use, non-intrusive, quick, and precise:

- Analyze samples of various sizes from entire car bodies, large aerospace parts, engines, mechanical actuators to micron-sized MEMS or delicate HDD components.

- From R&D to production and long-term monitoring, we have a Polytec system to provide the answer. Discover our low cost of ownership and high return on investment.

Learn more about our laser solutions for research & production today

Laser vibrometer products

Polytec’s laser vibrometers have become the globally recognized standard for non-contact vibration measurements. The extensive range of products offers you solutions to virtually any vibration-related issue in research, development, production and long-term monitoring.

Whether they are used for single-point or differential measurements, to determine rotational or in-plane vibrations, to visualize vibrations on MEMS and microscopic systems or for measuring and animating modal and operational deflection shapes: Polytec’s laser vibrometers provide a quick, non-contact and non-intrusive solution to your problem.

Single-point vibrometers

Single-point vibrometers

Single-point laser Doppler vibrometers measure transfer functions, amplitudes and resonance frequencies without contact in a non-intrusive way thanks to the simple “point and shoot” principle. Single-point vibrometers are laser vibration sensors that measure object vibrations in the direction of the laser beam (out-of-plane motions). From modular concepts to robust industrial vibrometers or compact designs – Polytec will always provide you with the ideal measuerement tool to solve your individual vibration measurement task.

Software

Software

Single-point laser Doppler vibrometers measure transfer functions, amplitudes and resonance frequencies without contact in a non-intrusive way thanks to the simple “point and shoot” principle. Single-point vibrometers are laser vibration sensors that measure object vibrations in the direction of the laser beam (out-of-plane motions). From modular concepts to robust industrial vibrometers or compact designs – Polytec will always provide you with the ideal measuerement tool to solve your individual vibration measurement task.

Full-field vibrometers

Full-field vibrometers

Full-field vibrometer are vibration measurement systems that allow engineers to conduct areal deflection shape measurements as fundament for validating simulation models and identifying vibration hotspots. They keep the focus firmly on complex vibration behaviour over the entire surface. Polytec’s product range includes everything from scanning vibrometers for stationary processes to multipoint vibrometers (that measure in parallel) for non-stationary and transient processes.

Service & Support

Service & Support

With our PolyXpert engineering services or system rentals, Polytec makes high-precision vibration analysis available to anyone. Benefit and use ultra-modern measuring technology straight away before investing in your own equipment. We support our customers in dedicated training sessions and with specific application support services.

Microscope-based vibrometers

Microscope-based vibrometers

Inspired by the rapid further development of microelectromechanical systems and MEMS, Polytec presents this highly innovative product line of microscope-based measurement systems. MSA Micr System Analyzers from Polytec validate dynamics and topography of microsystems reliably with utmost precision.

Special-application vibrometers

Special-application vibrometers

Special testing needs may require special measurement tools. Whether measuring ultrasonic applications in the very high frequency range, or rotational vibrations on rotating structures, or in-plane vibrations measured perpendicular to the measurement beam – there is a Polytec vibrometer ot provide the perfect solution.

Types of Vibration Tests

Modal Analysis

FE-Experimental Correlation

Troubleshooting

Noise Source

Strain/Stress

Transducer Development

Structural Health Monitoring

Inline Quality Control

Defect Detection