warranty on new sensors incl. laser diode

experience per PolyXpert

sensor exchange program

(excl. shipping)

awards in optical technology

Reduce maintenance, minimize scrap, optimize yield with Velocimeters

Polytec’s non-contact laser surface velocimeters (LSVs) deliver unmatched accuracy for continuous process measurement. Outperforming traditional contact methods, they enhance efficiency, reliability, and cost management. Trusted worldwide in industries like Steel and Aluminum, Tube and Pipe, Building Materials, Textiles, Film, Paper, Wire & Cable and more, Polytec LSVs optimize material usage, boost throughput, and ensure compliance with exacting specifications.

Steel, aluminum & metals

Steel, aluminum & metal

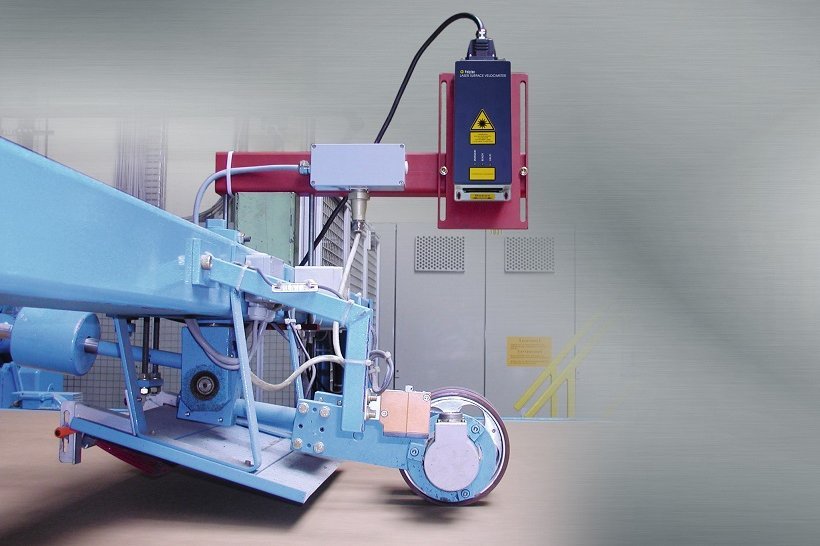

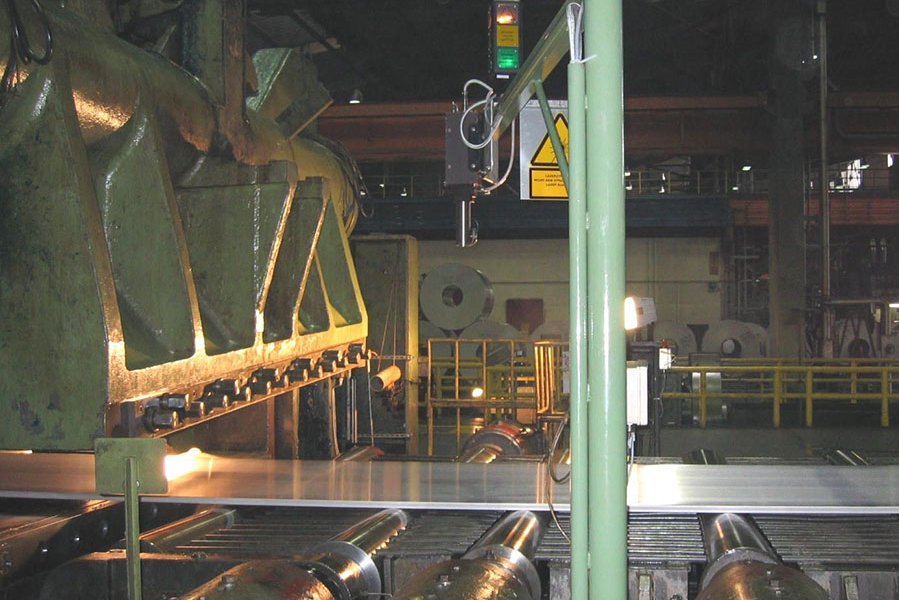

Non-contact length and speed measurement in production processes in the steel, aluminum and metal industry is the domain of Polytec LSV Laser Surface Velocimeters. High-precision measurement with laser accuracy in harsh conditions is what theses optical sensors were made for. LSV provide reliable measurement data for feedback on machining processes, process control and process optimization. Benefit from laser precision and non-contact measurement using Polytec LSV in order to optimize product quality, yield and avoid cost caused by overproduction slippage and wear. Monitor red-hot strand profiles without contact or measure skin-pass degrees with the utmost precision. LSV optical sensors help you with a wide range of sensors, offering you the optimum stand-off distances for your measurement application.

With over 20 years of experience in the industry and in laser measurement technology Polytec builds reliable velocity and length sensors that industrial customers can have confidence in. ProSpeed optical length and speed sensors help create solutions for a variety of applications in the metal industry. For instance, in continuous casting plants, hot and cold rolling mills, coating plants, pipe production and many more applications – LSVs do their job all over the world with the utmost reliability.

Application examples include:

- Elongation

- Velocity difference

- Velocity measurement

Length measurement

Mass flow regulation

Non-destructive testing

Cutting length control

Continuous casting

Wood & construction materials

Wood & construction materials

Precise, reliable and non-destructive length and velocity measurement is of the utmost importance when it comes to efficient manufacturing and processing in the wood and construction materials industry. Even the slightest deviations can cause added material costs, and these can quickly add up. For that reason high-precision, non-contact measurement techniques are indispensable.

Polytec's laser surface velocimeters (LSVs) have been specially designed for high-precision velocity and length measurement. These LSVs provide you with reliable measurement data that you can easily integrate into your process control systems. Using an LSV means increasing precision and thereby increasing the quantity and quality of your output. Your advantages: Polytec's non-contact measurement technique works on almost all surfaces without causing any damage. From cutting length control in glass wool right through to length measurement for roofing materials – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors support the wood and construction materials sector in quality inspections and sorting of lumbeer, length cutting of insulation materials, length verification of plasterboards, and in many more applications.

Application examples include:

- Velocity measurement

- Length measurement

- Cutting length control

- Position tracking

- Read/Write Head

Tube & pipe

Tube & pipe

Polytec’s Laser Surface Velocimeters have been specially designed for precise, reliable and repeatable measurement of length and speed in the tube and pipe Industries. Accessories such as cooling options, air wipes and mounting brackets make for reliable operation, even in harsh environments. With various outputs and interfaces, the LSV is easily integrated into process control systems for improved yield, increased throughput and reduced scrap. From seamless to welded tube, from stretch reducing to cut-to-length to weigh measure stencil – the Polytec product portfolio has what you need to achieve the optimum configuration for your application.

Applications: length, speed and position tracking in:

- Length and thickness positon tracking at stretch reducing mills

- Weld speed monitoring

- Cut-to-length

- Defect tracking in NDT

- 100% length inspection at weigh measure stencil

Converting, plastics & textiles

Converting, plastics & textiles

Precise, reliable and non-destructive length and velocity measurement is of the utmost importance in the converting and textile industry. Even the smallest deviation can cause added material costs which can quickly add up. That is why high-precision non-contact measuring processes are absolutely imperative.

Polytec's laser surface velocimeters (LSVs) have been specially designed for high-precision velocity and length measurement. Polytec LSVs provide you with reliable measurement data that you can easily integrate into your process control systems. Using an LSV means increasing precision and thereby increasing the quantity and quality of your output. Your advantages: Polytec's non-contact measuring technique works on almost all surfaces and removes any chance of damaging the measured product. From precision position monitoring in printing processes right through to cutting length control for packaging materials – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed optical length and speed sensors measure with the utmost reliability around the globe and support the converting and textiles industry...

- In printing processes

- in laminating and coating systems

- and many more applications

Paper, cardboard & packaging

Paper, cardboard & packaging

Precise, reliable and non-destructive length and velocity measurement is of the utmost importance when it comes to manufacturing and processing in the paper industry. Even the smallest deviation can cause added material costs, and these can quickly add up. That is why high-precision non-contact measuring processes are of the greatest importance.

Polytec's laser surface velocimeters (LSVs) have been specially designed for high-precision velocity and length measurement. These LSVs provide you with reliable measurement data that you can easily integrate into your process control systems. Using an LSV means increasing precision and thereby increasing the quantity and quality of your output. Your advantages: Polytec's non-contact measuring technique works on almost all surfaces and rules out any chance of damage being caused by measuring devices. From precision position monitoring in printing processes right through to cutting length control for packaging materials – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors measure with the utmost reliability in companies all around the world and support manufacturing processes in paper factories, printing processes, and many other paper, cardboard and packaging processes.

Application examples include:

- Velocity difference

- Velocity measurement

- Length measurement

- Tension control

Cables & wires

Cable & wire

Precise, reliable and non-destructive length and velocity measurement is of the utmost importance when it comes to efficient manufacturing and processing in the cable and wire industry. The slightest deviations can cause added material costs, which can quickly add up. That is why high-precision non-contact measuring processes are essential.

Laser length and speed sensors, also called laser surface velocimeters (LSV) have specially been designed for accurate and reliable lenght and speed measurement in production processs. LSVs provide reliable measurement data that you can easily integrate into your process control systems. Using LSV means increased precision and thereby increased quantity and quality of your output. Polytec's non-contact measuring technique works on almost any surface and avoids damaging the produced good. From precision length measurement when winding cables right through to velocity measurement in coating processes for fiber optic cables – Polytec systems ensure that you obtain the perfect configuration for every application.

ProSpeed® optical length and speed sensors support the manufacturing of cable and wire...

- in printing processes

- in wire drawing

- in insulating and sheathing lines

- in marking and printing processes

- and many more applications

Application examples include:

- Length measurement

- Velocity measurement

- Cutting length control

Learn more about LSV Laser Surface Velocimeters

Typical ProSpeed® optical encoder applications

Speed measurement

Speed measurement

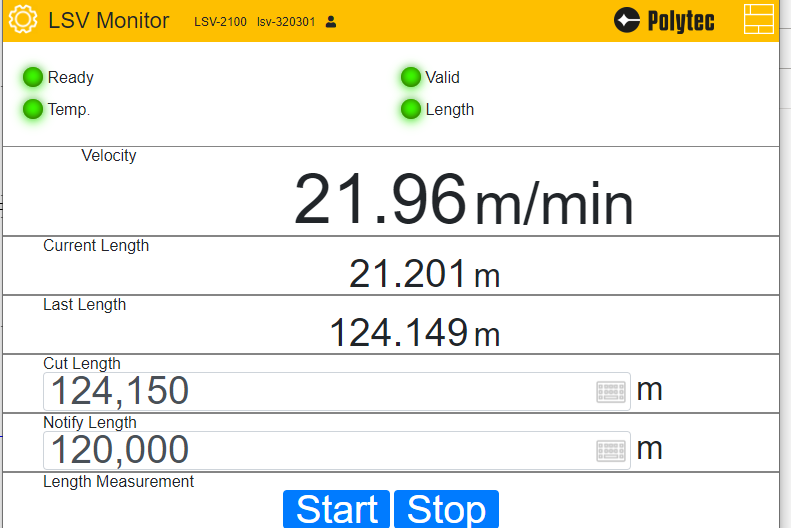

Process speed or velocity measurement is the basis for many steps in production processes such as cut-to-length control, depending on the manufacturing process sometimes speed synchronization, or differential speed measurement and more. In these processes, optical speed encoders use the laser Doppler effect for precise speed measurement, avoiding contact of the encoder with the good's surface and preventing slippage and wear, resulting in utmost precision and reliability in process control.

Length measurement

Length measurement

Whether in casting processes, rolling mills or any cut-to-length control, length verification of cut products such as rods, tubes, coils, panels and sheets, plate positioning in U- and O-presses for tubes, material tracking for sheet materials, winding sheet material up to position sensing and elongation, with length of a final or semi-finished product being the key factor for process control, laser encoders like ProSpeed LSV have become the established optical sensor of choice in many production lines.

Cut-to-length, casting and rolling mills

Cut-to-length, casting and rolling mills

Providing electrical signals just like any classic encoders, optical encoders can seemlessly be integrated into manufacturing lines for inline measurement. Laser encoders show exceptional performance in challenging conditions such as red-hot metals, humid and hot or dustry production environments, providing stable and all-time reliable measurement signal for continuous production, reducing measurement uncertainty caused by slippage or wear.

Our PolyXpert services measure customer satisfaction

3 year warranty including laser diode

Polytec stands behind the durability and performance of its optical sensors by offering an industry-leading 3-year warranty. This reflects our confidence in the quality and longevity of our products.

Swift reaction times

We stand by your side, proved by our typical reaction times below 4hrs per phone, 24hrs per e-mail and onsite support scheduled on request. We set your demands of modern production environments as our priority.

Always ready - sensor exchange program

Our sensor exchange program ensures continuous production by providing a seamless and efficient process for replacing sensors - usually within 24 hours (plus shipping, transition etc). When it comes down to issues, we help minimize disruptions and hold up your productivity.

Commissioning & on-site support

Planning your next project? We offer early-stage assistance with our expertise in industrial processes. Request a demonstration and on-site proof-of-concept. We provide custom integration with a wide range of application-specific accessories, ensuring your production line's needs are met. Our services include professional onsite commissioning and support from mechanical to data integration.

Schedule your calibration & maintenance

Uncompromised quality management, compliance according to ISO:9001 or others? Plan your next move and stay on the safe side. Scheduled calibration and repair is usually done in two working days. We offer calibration services, and ongoing maintenance support to guarantee the optimal performance of our optical sensors.

Trainings

Our global team shows an average of over 10 years of experience in the field, bringing unparalleled knowledge in a broad variety of industries. Upon request we also offer worldwide trainings to share our knowledge and experience and help you make the most of your investment.

Learn more about non-contact speed and length measurement

Encoder integration using Fieldbus protocols: Ethernet-IP, Profinet and more

The latest generation of ProSpeed® encoders are laser sensors with compact design and all-in-one integrated optics and electronics. Their enhanced connectivity concept results in a seemless and easy integration into your production line. Use comprehensive accessories for your custom encoder and process control solution. Contact us for free demos and customization by our dedicated PolyXpert service and support team.

How it works: optical encoders for in-line process control

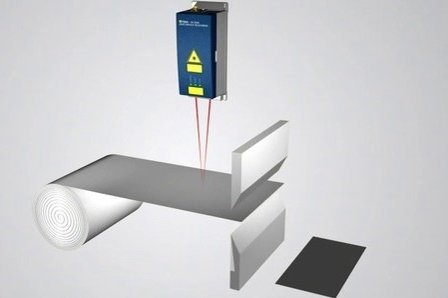

ProSpeed® as the optical alternative sensor solution compared to encoders or encoder wheels use the laser Doppler effect to evaluate the laser light scattered back from the moving object. Two laser beams super-imposed on the surface generate an interference pattern of bright and dark fringes. As the surface moves through the fringe pattern, the intensity of the light scattered back modulates in frequency. This modulation frequency measured by the photo receiver of the sensor system is directly proportional to the surface velocity.

Optical encoders promise reliable measurement data

Polytec optical length and speed encoders, so called LSV Laser Surface Velocimeters, are established optical sensors in many applications to optimize the process by reducing process variability. LSV are established length and speed encoders installed in applications such as cut-to-length control, part-length verification, total length on winders, line speed, differential line speed for stretch or elongation and many more. Avoid process uncertainty and added costs caused by contact measuring techniques like encoder wheels due to slippage, wear, damage to the product or maintenance.