warranty on new profilers

experience per PolyXpert

satisfied customers worldwide

awards in optical technology

Characterize your surface in 3D

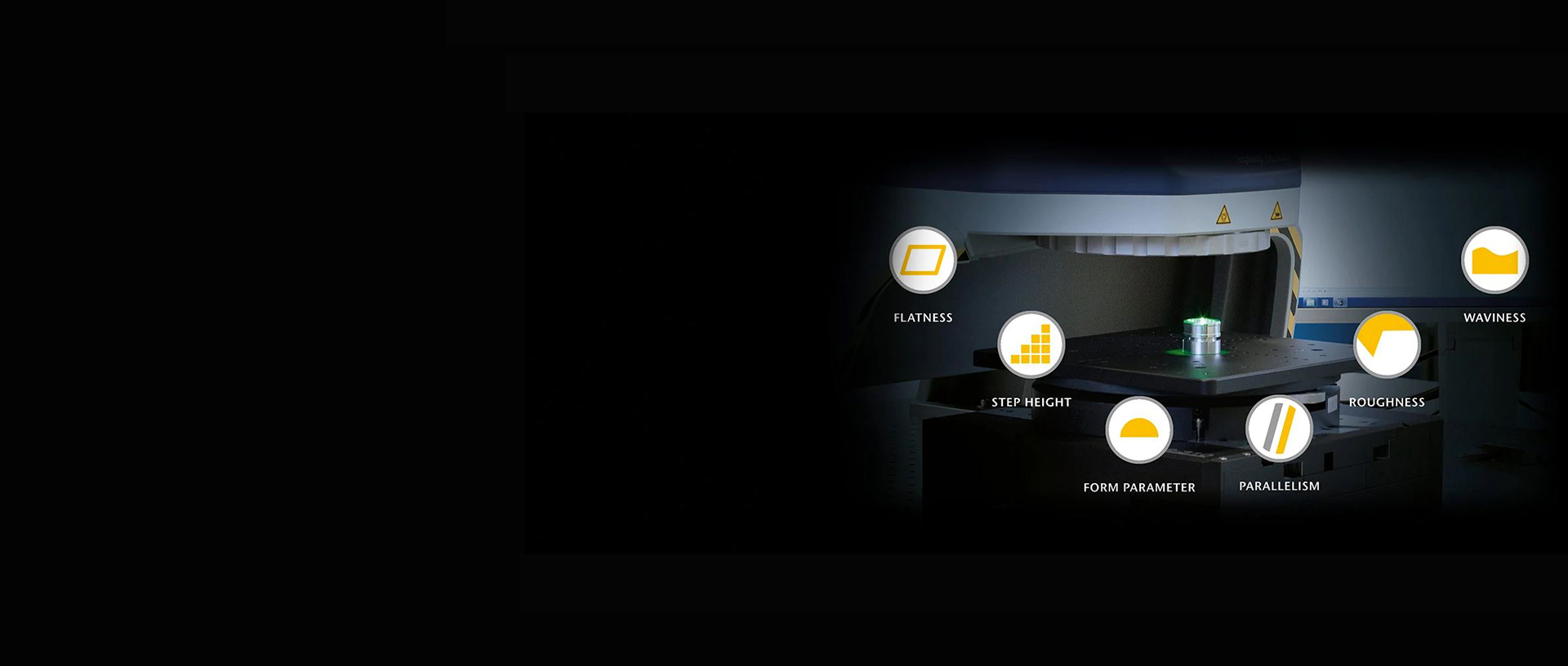

Roughness

Roughness

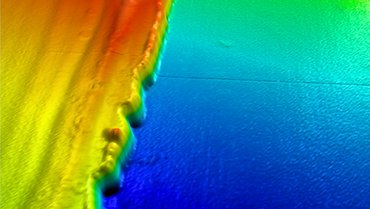

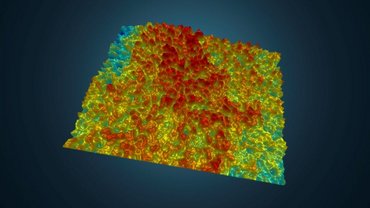

Areal surface roughness measurement data provides an easy and complete view of an entire surface. In contrast, a profile measurement contains only a limited section of the entire surface and is less intuitive. Optical profilometers are increasingly replacing tactile measuring systems. Eventually in the near future, 2D parameters will only endure where their informative value is sufficient. A comprehensive and full 3D characterization of the entire sample surface e.g. by using optical surface metrology like TopMap whitelight intefereometers offers an intuitive visualization of measurement data while permiting extensive evaluation options for a deeper analysis and feedback on the production process.

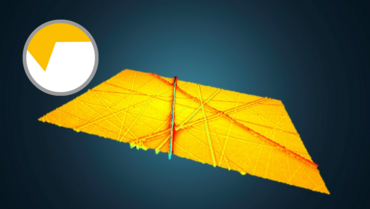

Flatness

Flatness

Surface flatness tolerances are defined for many manufactured parts since flatness is crucial for many applications in order to ensure functionality of technical components. With flatness being an essential surface parameter, it influences e.g. the leakage of sealing surfaces on flanges and valve seats. In precision optics where optical polishing is applied, the flatness of e.g. glass substrates, optical mirrors or beam splitters is one of the most important quality indicators. But not only precision mechanics and optical components widely use flatness tolerances. In the electronics industry it is important to know whether the flatness of PCBs is within specified tolerances to ensure electrical connectivity when attaching multiple parts e.g. via soldering process. For surfaces that move relative to each other, surface flatness can also affect noise levels and sound emission of components. Simply put, flatness tolerances widely influence product reliability, functionality and even noise.

Step-height

Step-height

The inspection of step height plays an important role in quality inspection. For this reason, many technical drawings contain tolerance specifications for height dimensions, for example for shoulders, grooves and bores. If the specifications for step height are violated, disadvantageous gap dimensions occur or two component surfaces come into unintentional contact. This can lead to leakage at sealing surfaces, interrupted current flow at electrical contacts or increased frictional resistance and wear. In addition, the step height measurement can also be used to optimize build-up or ablation manufacturing processes; both the thickness of non-transparent layers can be determined and the material removal e. g. by laser pulses can be checked.

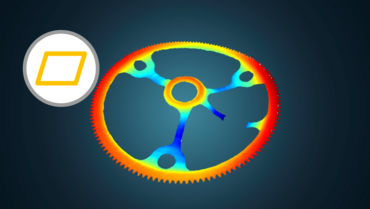

Microstructures

Microstructures

Using the versatile surface measurement systems from Polytec, you can complete your micro and nano technology tasks reliably, quickly and with a high level of precision. You can eject channel depths on your lab-on-a-chip, determine the step height on MEMS packaging, establish how flat pressure sensors are and analyze MEMS using surface parameters. Even performing dynamic out-of-plane and in-plane measurements on RF filters to determine MHz resonance frequencies will be a simple task.

Layer thickness

Layer thickness

The scratch test is a popular adhesion test for thin, hard and well-adhering coatings such as TiC (titanium carbide) on steel or cemented carbide substrates. Coating thickness measurement of non-transparent materials can also be measured at the edge of a coating or by a step-height measurement of the scratch. Layer thicknesses from a few μm upwards can be detected on transparent coatings at any position.

A wide variety of surface defects in coating and metallizing can be measured, qualified and catalogued, including voids, streaks, chatter, droplets, spots, dimples, holes, scratches, coating disturbances, contaminants, orange peel, and visual texture appearance. Defects can be quickly visualized, measured and the information used to help identify its cause, so that process cures can be quickly implemented, optimized and then monitored to show the improvements in end coated surface quality control. Defects can be measured and qualified on a coating to help identify the cause.

Texture

Texture

Surface texture defines the topographical features of a workpiece surface, including characteristics such as roughness, waviness, and lay. These parameters may affect the performance, appearance, friction, corrosion resistance, fatigue behavior and thus the functionality of a component. So the surface texture influences a wide range of products, whether in industrial machines and systems, medical devices or consumer goods. Surface texture is crucial throughout industries including manufacturing, automotive, aerospace, and electronics.

TopMap optical profilers provide 3D texturing measurement data based on precise height data by large areal scanning technique, enabling fast and repeatable measurements and reliable results.

Learn more about our Surface Metrology solutions

Characterize entire workpiece topographies in 3D

Benefit from innovative, high-precision and non-contact measurement

Use large vertical range, sub-nm resolution for clearest view

Areal measurement with large field of view

Reproducible measurement of surface flatness, step height, parallelism, roughness etc.

From micro to macro size samples

For labs, production level and in-line testing

4 year warranty and lifetime software updates

Profilers with large FOV (44x33…230x220 mm) or sub-nm Z resolution

TopMap Micro.View

TopMap Micro.View

TopMap Micro.View® is an easy to use and compact optical profiler. Choose Micro.View® as the cost-effective quality control solution for surface analysis of precision-engineering, for inspecting roughness, microstructures and more surface details.

TopMap Micro.View+

TopMap Micro.View+

TopMap Micro.View®+ is the next generation optical surface profiler in a modular design to reliably measure the most challenging analysis tasks regarding surface finish and microstructures with utmost precision. Focus Finder and Focus Tracker assist in keeping samples focused at all times, with fully motorized positioning units ready for automation.

TopMap Pro.Surf

TopMap Pro.Surf

Pro.Surf stands for fast and professional 3D surface characterization: Capturing 2 million measurement points just wihtin seconds make sure to see every detail. Pro.Surf masters challenging production workflows with short measuring times. The exceptionally large field-of-view (FOV) caputes big samples with image fields up to 33x44 mm in a single shot - while stiching expands to 230x220 mm with the flexible 70 mm Z range.

TopMap Pro.Surf+

TopMap Pro.Surf+

The all-in-one 3D optical metrology solution from Polytec. This ultra precise white-light interferometer combines a chromatic confocal sensor for roughness profiles with an areal measurement of geometrical paramters and form deviation in a multi-sensor system. Pro.Surf+ is the choice to measure both the topography of large sampels with a large field of view (FOV) while also characterizing structural details with nanometer resolution.

TopMap Metro.Lab

TopMap Metro.Lab

This compact and complete surface metrology workstation is the perfect entry into the world of optical, non-contact surface characterization with a large field of view (FoV). TopMap Metro.Lab is the ideal for labs and close to production quality control, offering a great value for money and therefor being especially attractive for smaller companies with non-frequent or sporadic testing needs.

In-house & on-site testing services, rentals and leasing

In-house & on-site testing services, rentals and leasing

Our PolyXperts are looking forward to supporting you with flexible and custom measurement services in our modern labs or at your site - also remotely as online session! We’d be happy to guide and consult you at any stage. Besides outsourcing, ask for our rentals and leasing for expanding your capabilities on shorter notice.

Polytec stands behind the durability and performance of its surface metrology systems by offering a unique 4-year warranty, reflecting our confidence in the quality and longevity of our optical profilers. Gain even more peace of mind with our industry leading PolyCare program.

Customization

Sometimes our 44x33 mm large field of view (stitching 230x 220) is not enough or you need specific sample holders or vibration isolation. Sometimes our CST Continuous Scanning Technology with up to 100 mm vertical measurement range is just a piece of your puzzle. Sometimes our <nm resolution topography requires additional insights and evaluation. We offer custom software + hardware + optics as one-stop service, whether custom parameters or implementing measurement routines, we finetune our surface topography solutions upon your specification.

See how it works: Request your complimentary sample analysis

Step 1:

Discuss your needs with our experts.

Step 2:

Send us your sample or visit our lab. We'll handle the measurement.

Step 3:

Receive your detailed report and discuss the results with our team.

Optical 3D surface profiling across industries

TopMap surface metrology systems are high-precision instruments designed for inspecting the surface structure of precision components. Using a non-contact method, these white-light interferometers can achieve measurements with resolutions down to the subnanometer range. Polytec's optical 3D surface metrology has become a standard in industrial quality control. Applications span across various sectors, including automotive, aviation, semiconductor, electronics, biology, and medicine. Which industry are you in?

Microtechnology and nanotechnology

Microtechnology and nanotechnology

Using the versatile surface measurement systems from Polytec, you can complete your micro and nano technology tasks reliably, quickly and with a high level of precision. You can eject channel depths on your lab-on-a-chip, determine the step height on MEMS packaging, establish how flat pressure sensors are and analyze MEMS using surface parameters. Even performing dynamic out-of-plane and in-plane measurements on RF filters to determine MHz resonance frequencies will be a simple task.

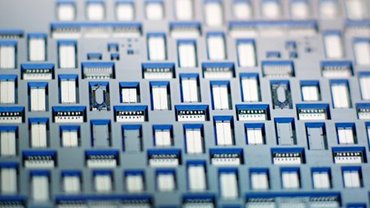

Electronics, semiconductors and solar

Electronics, semiconductors and solar

You can ideally adapt Polytec’s versatile solutions in the semiconductor industry for your applications in the electronics and solar technology industries. In the field of software, for example, you can do so by utilizing application-specific user interfaces for the OK / NOK analysis. Polytec offers you solutions to check electronic contacts – both for analyzing the height of BGAs or “solder bumps” and for analyzing the co-planarity of IC pins. You’ll also find the right systems for packaging high-power laser diodes at Polytec.

Glass and transparent materials

Glass and transparent materials

Find efficient measurement and testing solutions for quality inspection or manufacturing control of glasses or other transparent materials within the range of optical 3D surface metrology systems from Polytec. These product lines offer you flexible and easy-to-use systems for measuring thickness or determining form parameters such as flatness. Polytec also offers you customized solutions depending on roughness, distance or thickness requirements. If you’d like to perform measurements quickly right there on the production line, then the chromatic confocal technology can help. But if you’re looking to carry out an areal thickness analysis at millions of points, then you should opt for the TopMap series.

Automotive

Automotive

In the automotive industry, technical surfaces tip the scales when it comes to high-precision mechanics and their performance. The dimensional tolerance has a decisive influence on a product’s fuel and energy efficiency, eco-friendliness and durability. From sealing surfaces, to the drivetrain and shock absorbers and to injection systems, there are a multitude of applications “being put to the test”. Absolute precision when contactlessly determining flatness, parallelism, form parameters, surface parameters, heights and steps is vitally important. And what should you use to ensure this? The surface measurement systems from Polytec, of course!

Data storage

Data storage

Hard disk drives are everywhere, and everyone is reliant on them working reliably and perfectly. To guarantee these essential aspects, manufacturers and their suppliers devote much of their energies to development and manufacturing. Polytec gives them a helping hand in this regard. Whether you’re dealing with hard drive bearings, hard drive disks or write / read heads, Polytec’s range of surface metrology products help you to boost reliability in your production processes.

Steel, aluminum & metals

Steel, aluminum & metals

Surface quality in the micrometer and sub-micrometer range plays a key role in the lifecycle of products made from metal. Particularly for functional surfaces, compliance with tolerances is crucial to ensuring the subsequent products’ reliability and durability, even at the raw materials production stage. Surface measurement systems from Polytec offer you contactless measurement results with micrometer and nanometer resolution that can be reproduced at any time for precisely this purpose. While you can use the chromatic confocal sensors to analyze roughness profile lines as 2D parameters, you can use the TopMap large-field-of-view systems to areally detect form deviation and to characterize surface function and quality based on surface parameters such as flatness, ripple and parallelism even in 3D. The 2D measurement data is evaluated in line with DIN ISO 4287 / 4288, while the 3D measurement data is evaluated according to DIN ISO 25178.